A Quick Guide by Nuke NDT

In the world of industrial manufacturing and quality control, Non-Destructive Testing (NDT) plays a crucial role in ensuring product safety and reliability. Among various NDT methods, Magnetic Particle Inspection (MPI) is widely used for detecting surface and near-surface defects in ferromagnetic materials due to its high sensitivity and operational efficiency.

With the advancement of automation and AI technology, a new generation of equipment has emerged—Automatic Magnetic Particle Inspection Systems with Intelligent Defect Recognition, and Nuke NDT is proud to be at the forefront of this transformation.

🔍 The Principle Behind Magnetic Particle Inspection

MPI works by magnetizing a ferromagnetic material. If a surface or subsurface discontinuity is present, it distorts the magnetic field and causes a magnetic flux leakage. When magnetic particles (dry powder or fluorescent suspension) are applied, they accumulate at the leakage field, revealing the defect’s shape and location.

🤖 What is an “Automatic Recognition” MPI System?

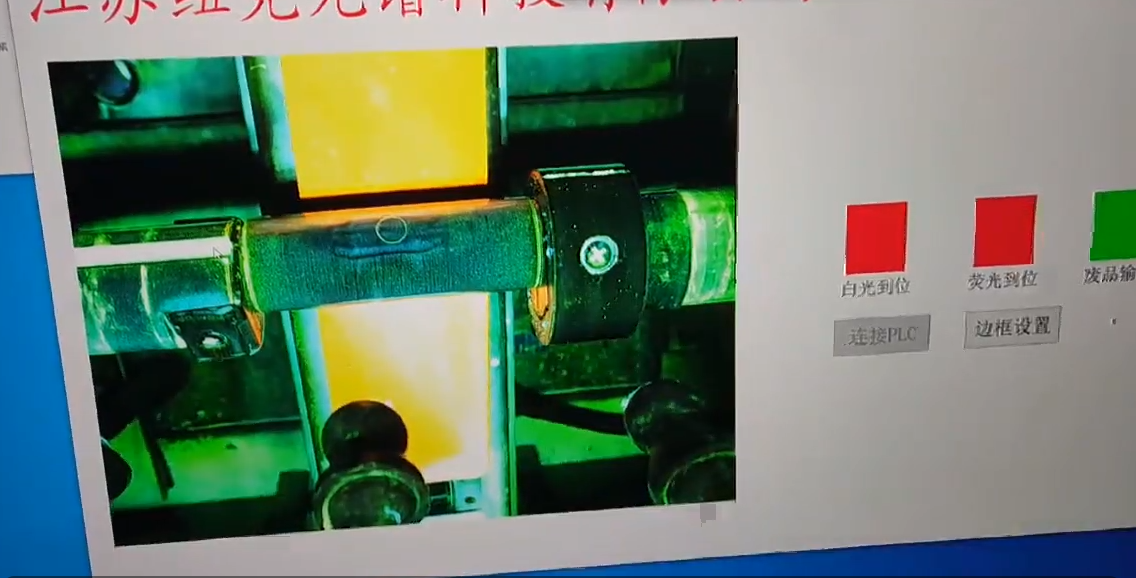

Traditional MPI often relies on manual visual interpretation, which can be time-consuming and operator-dependent. In contrast, Nuke NDT’s automatic MPI systems integrate advanced technologies to deliver faster, more accurate, and consistent inspection results.

Key Features:

-

High-Resolution Image Capture

Equipped with industrial-grade cameras to clearly capture magnetic particle indications under UV lighting. -

AI-Powered Defect Recognition

Intelligent image processing algorithms analyze patterns and shapes to automatically detect and classify defects. -

Automated Judgement and Report Generation

The system instantly decides pass/fail status based on preset criteria and saves data for traceability. -

In-Line Integration

Seamlessly integrates into automated production lines for real-time inspection and sorting.

✅ Advantages of Nuke NDT Automatic MPI Systems

| Benefit | Description |

|---|---|

| Minimized Human Error | Reduces reliance on inspector skill and fatigue |

| Higher Throughput | Ideal for large-scale, continuous operations |

| Greater Accuracy | Detects even micro-defects with precision |

| Traceable Records | Automatic report generation with images |

| Customizable Design | Tailored to fit different part geometries and industry standards |

🌍 Widely Applied Across Industries

Nuke NDT automatic MPI systems are trusted in a wide range of sectors:

-

🔩 Fastener Manufacturing – bolts, screws, shafts

-

✈️ Aerospace Components – critical flight parts

-

🚢 Marine Industry – propeller shafts, anchors

-

🛢 Petrochemical Equipment – pressure vessels, weld seams

-

⚙️ General Machining – axles, gears, forged parts

🚀 Looking Ahead

As artificial intelligence and machine vision continue to evolve, Nuke NDT will keep innovating to deliver smarter, more efficient, and more connected NDT solutions. Automatic recognition MPI is not just a tool—it’s the foundation for digital quality control in smart manufacturing.

Interested in upgrading your inspection process?

Contact Nuke NDT today to learn more about our full line of magnetic particle inspection systems and custom solutions.

📧 irene@nksmartmeter.com