The Semi-Automatic Penetrant Testing Line is widely used in a variety of industries where surface integrity and defect detection are critical. It is especially suitable for non-destructive testing of components with complex shapes, fine surface finish, or high safety requirements.

🔧 Aerospace Industry

Used for the inspection of aircraft engine components, turbine blades, landing gear, and structural parts, where strict compliance with standards like ASTM E1417 and NADCAP is required.

🚗 Automotive Manufacturing

Applied in the detection of surface cracks on key parts such as camshafts, crankshafts, suspension components, and brake system parts to ensure safety and performance.

⚙️ Precision Casting and Forging

Ideal for testing cast and forged parts such as valves, housings, pump bodies, and tools, especially in industries requiring high dimensional accuracy and structural integrity.

⛽ Petrochemical and Energy

Used for the inspection of pressure vessels, pipelines, heat exchangers, and welded structures in oil & gas, nuclear, and power generation sectors.

🚢 Shipbuilding and Marine Engineering

Essential for surface flaw detection on weld seams, propeller shafts, rudder parts, and marine engine components exposed to corrosion and dynamic loads.

🏗️ Machinery Manufacturing

Applicable to heavy machinery, tooling, bearings, and rotating parts to prevent early-stage failures due to surface discontinuities.

📌 Customizable for Your Industry

Whether your focus is aerospace compliance or high-throughput automotive part testing, our Semi-Automatic Penetrant Testing Line can be configured to meet your specific part size, throughput needs, and industry regulations.

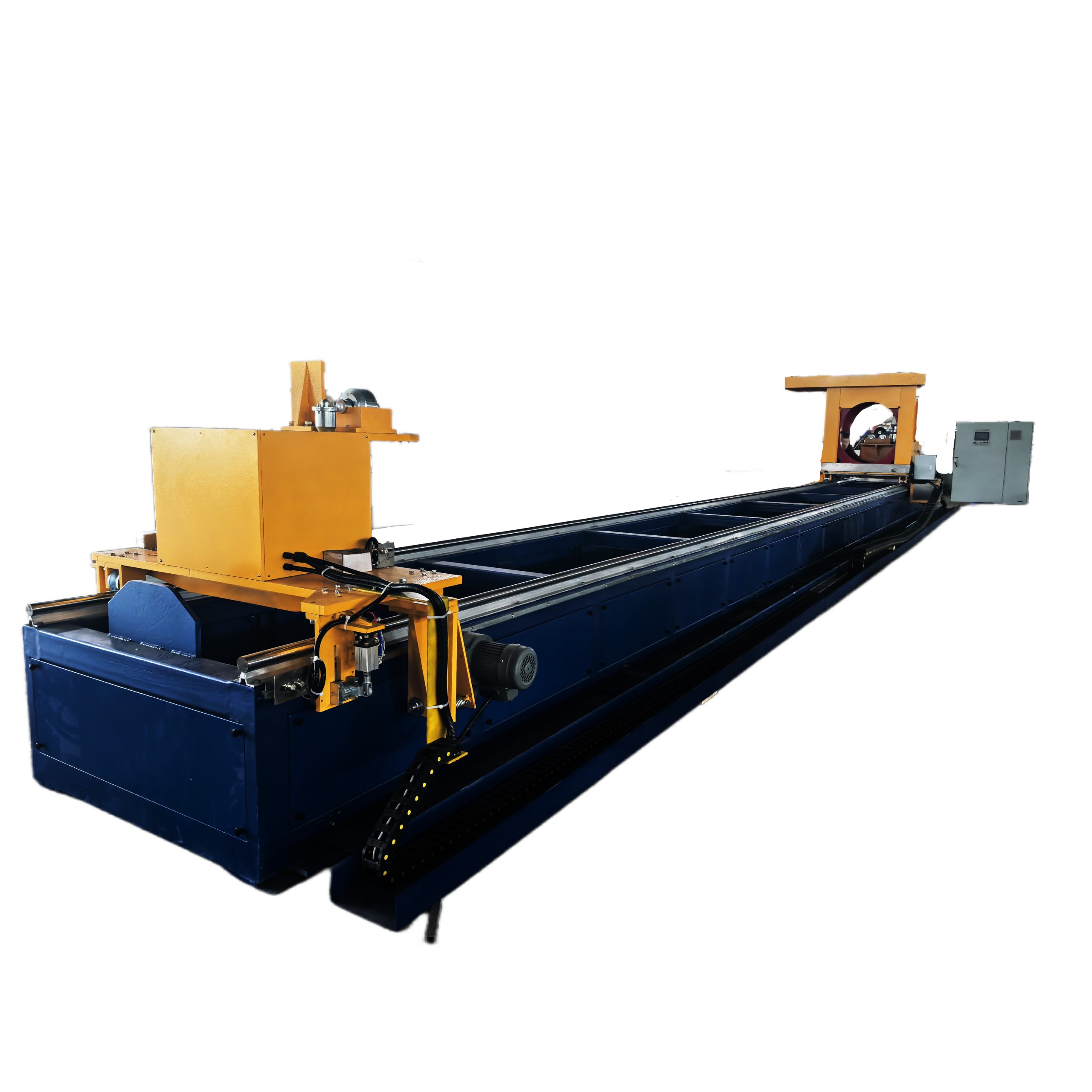

NKPT1800 Semi-Automatic Penetrant Testing Line for Precision Surface Flaw Detection

Nuke Non–Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.