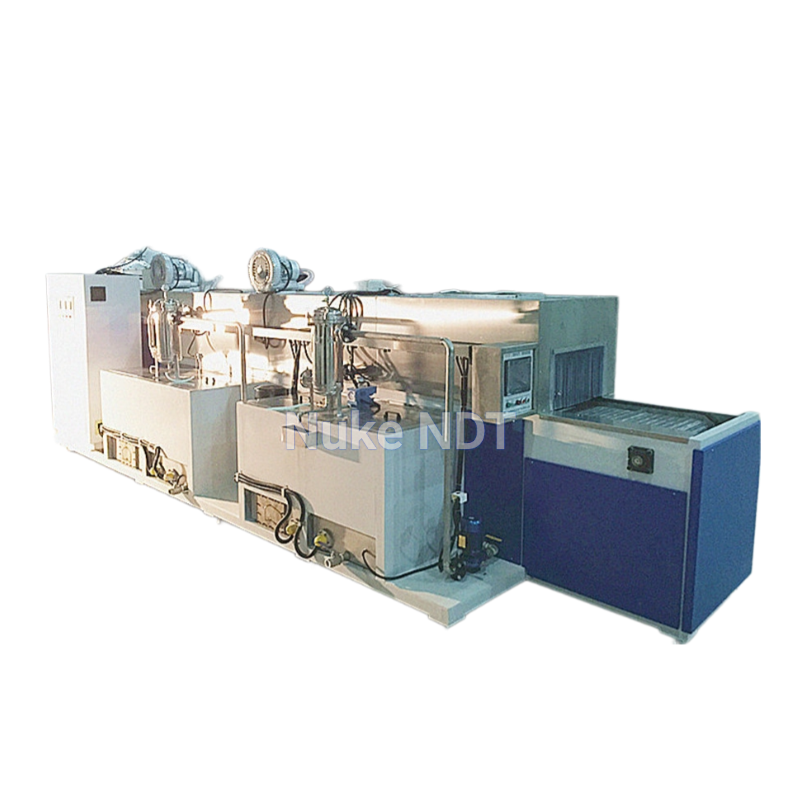

Ultrasonic Cleaning Machine

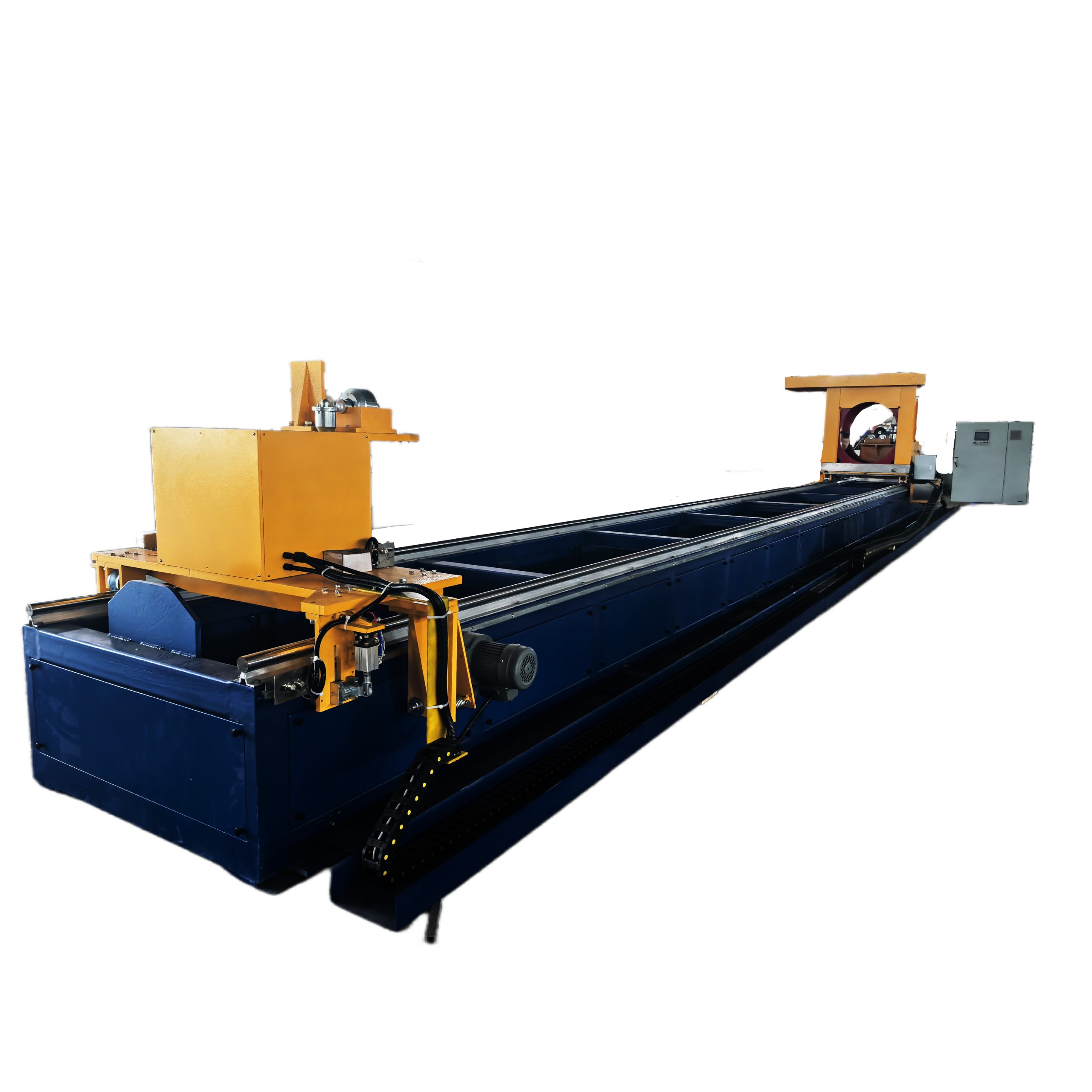

Nuke Non – Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle flaw detectors, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.