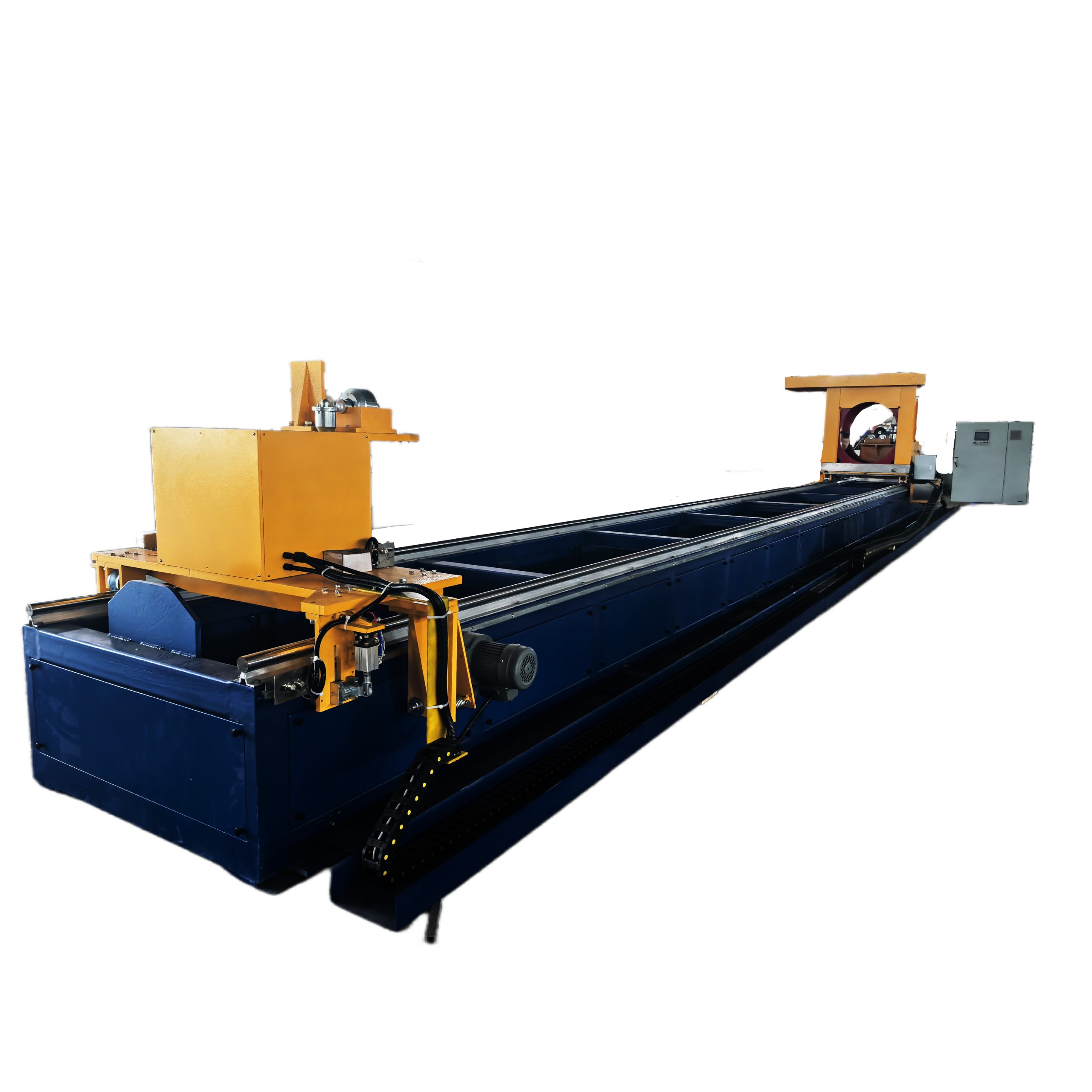

Horizontal Fluorescent Magnetic Particle Inspection Machine for Valve Bodies Dual Station

Nuke Non–Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing and marketing service system, ensuring high efficiency and reliable product performance. With the aid of computer-aided design (CAD) and a professional technical team, our products are developed with precision and optimized for real-world industrial applications.

Our equipment is widely used in critical sectors where safety and quality are paramount, including:

Aerospace and Aviation

Military and Defense

Railways and Locomotive Manufacturing

Automotive and Motorcycle Production

Shipbuilding and Marine Engineering

Oilfield and Petrochemical Industry

Boilers and Pressure Vessels

Bearings, Gears, Springs, and Standard Parts Manufacturing

Diesel Engines, Tractors, and Agricultural Machinery

Power Generation and Chemical Processing

Driven by technological innovation and a commitment to customer satisfaction, Nuke continues to expand its presence both in domestic and international markets. With reliable quality, responsive service, and a strong reputation, we have earned the trust of partners across various industries.

At Nuke, we are committed to delivering intelligent, efficient, and practical NDT solutions to help our customers improve quality control and enhance operational safety.

Contact us today to find more NDT solutions.