The CNK3000 Long Shaft Magnetic Particle Inspection Machine is widely used across multiple industries requiring high-precision, non-destructive testing of long shaft components and cylindrical parts. Its robust design and versatile inspection capabilities make it an essential tool for quality assurance in the following application fields:

-

Automotive Industry

The CNK3000 is ideal for inspecting critical automotive components such as drive shafts, crankshafts, and axles. It helps detect surface cracks, fatigue fractures, and other defects early in the production process, ensuring vehicle safety and performance.

-

Heavy Machinery Manufacturing

In construction equipment, agricultural machinery, and industrial machines, long shafts and rotating parts undergo intense stress. This inspection machine ensures the structural integrity of components like rotor shafts, gear shafts, and transmission shafts, reducing the risk of unexpected failures.

-

Aerospace and Aviation

Safety-critical aerospace components demand the highest inspection standards. The CNK3000’s high sensitivity and precise magnetization detect minute flaws in turbine shafts, landing gear parts, and control rods, supporting compliance with rigorous aerospace regulations.

-

Marine and Shipbuilding Industry

Long shaft inspection is crucial for ship propeller shafts, rudder stocks, and other maritime components exposed to harsh environments. This device provides reliable defect detection to prevent costly damages and ensure operational safety at sea.

-

Military and Defense

The machine is used for non-destructive testing of various defense equipment components, including artillery barrels and armored vehicle drive shafts, where safety and reliability are paramount.

-

Energy Sector

Power generation equipment such as turbines, generators, and pump shafts benefit from thorough inspection with the CNK3000, helping avoid downtime and prolong equipment life.

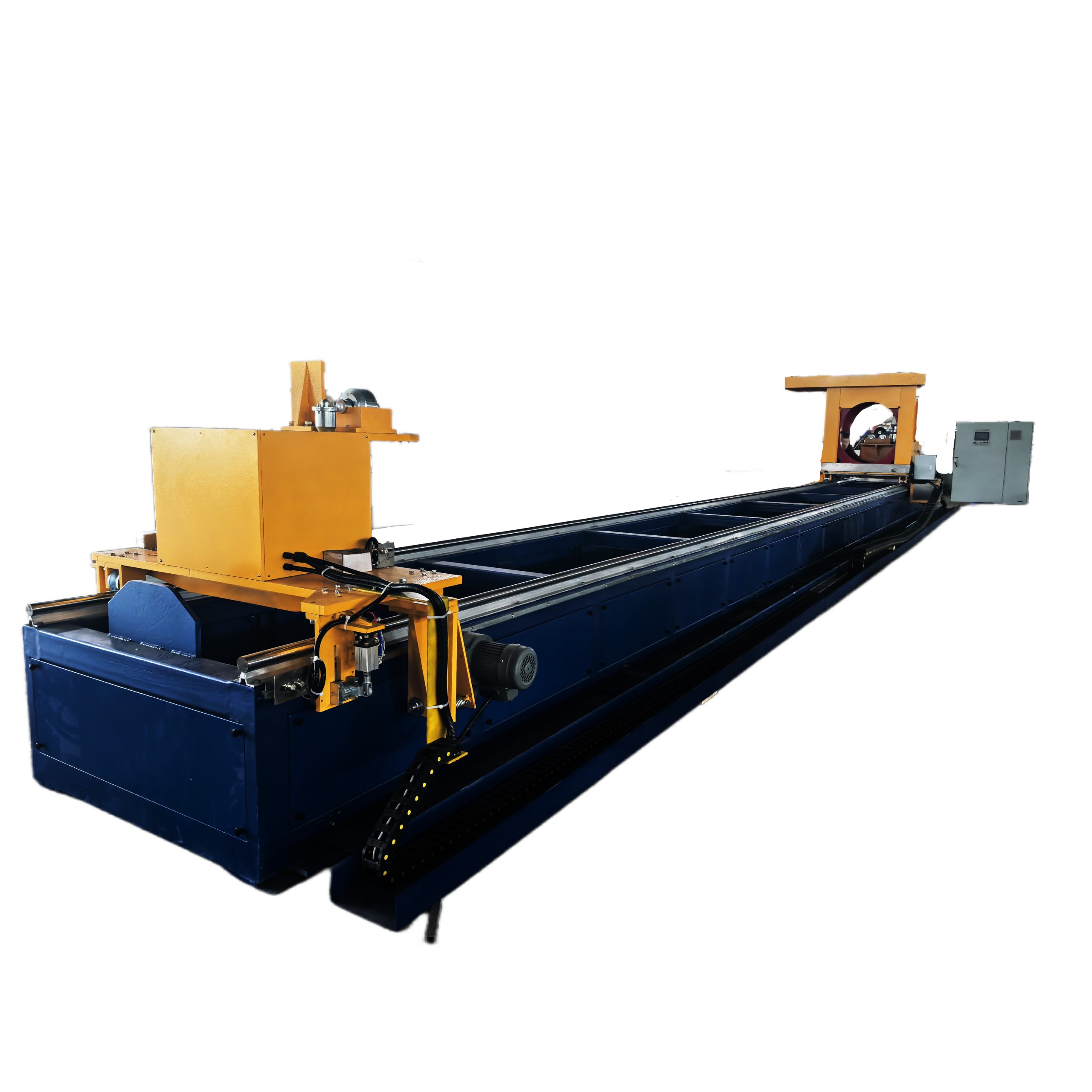

CNK3000 Magnetic Particle Testing Machine for Long Shaft Inspection NDT Equipment for Automotive & Machinery Parts

Nuke Non – Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.