Our handheld rechargeable UV LED lamp is widely used in various industries that require precise, portable, and reliable fluorescent inspection. Below are the key application areas where this product delivers exceptional performance:

1. Non-Destructive Testing (NDT)

-

Used for fluorescent magnetic particle inspection (FMPI) and fluorescent penetrant inspection (FPI) to detect cracks, surface defects, and weld integrity.

-

Ensures reliable defect detection under UV-A light (365nm range).

-

✅ Ideal for aerospace, automotive, and structural testing

2. Automotive & Aerospace Industry

-

Supports quality control in component manufacturing, assembly, and maintenance.

-

Used to inspect engine parts, brake systems, landing gear, turbines, and other critical components.

-

Helps meet stringent safety and durability standards.

3. Leak Detection

-

Detects leaks in HVAC systems, pipelines, fuel systems, and refrigeration units by highlighting fluorescent tracer dyes.

-

Enables quick identification of microleaks that are invisible under normal lighting.

4. Forensics & Security Inspection

-

Used in crime scene investigations, counterfeit detection, and document verification.

-

Reveals hidden biological stains, security marks, and ink variations.

5. Laboratory & Scientific Research

-

Used for biological fluorescence observation, chemical tracing, and UV-reactive material studies.

-

Offers stable output and low heat, suitable for controlled environments.

▶ Add Media: Lab technician using UV lamp on petri dishes or slides

6. Electronics Manufacturing

-

Inspects solder joints, PCB coatings, and adhesive integrity using UV-curable materials.

-

Ensures precision in microelectronic assembly lines.

▶ Add Media: PCB inspection under UV light

CJ100 Portable Rechargeable Handheld UV Inspection Lamp

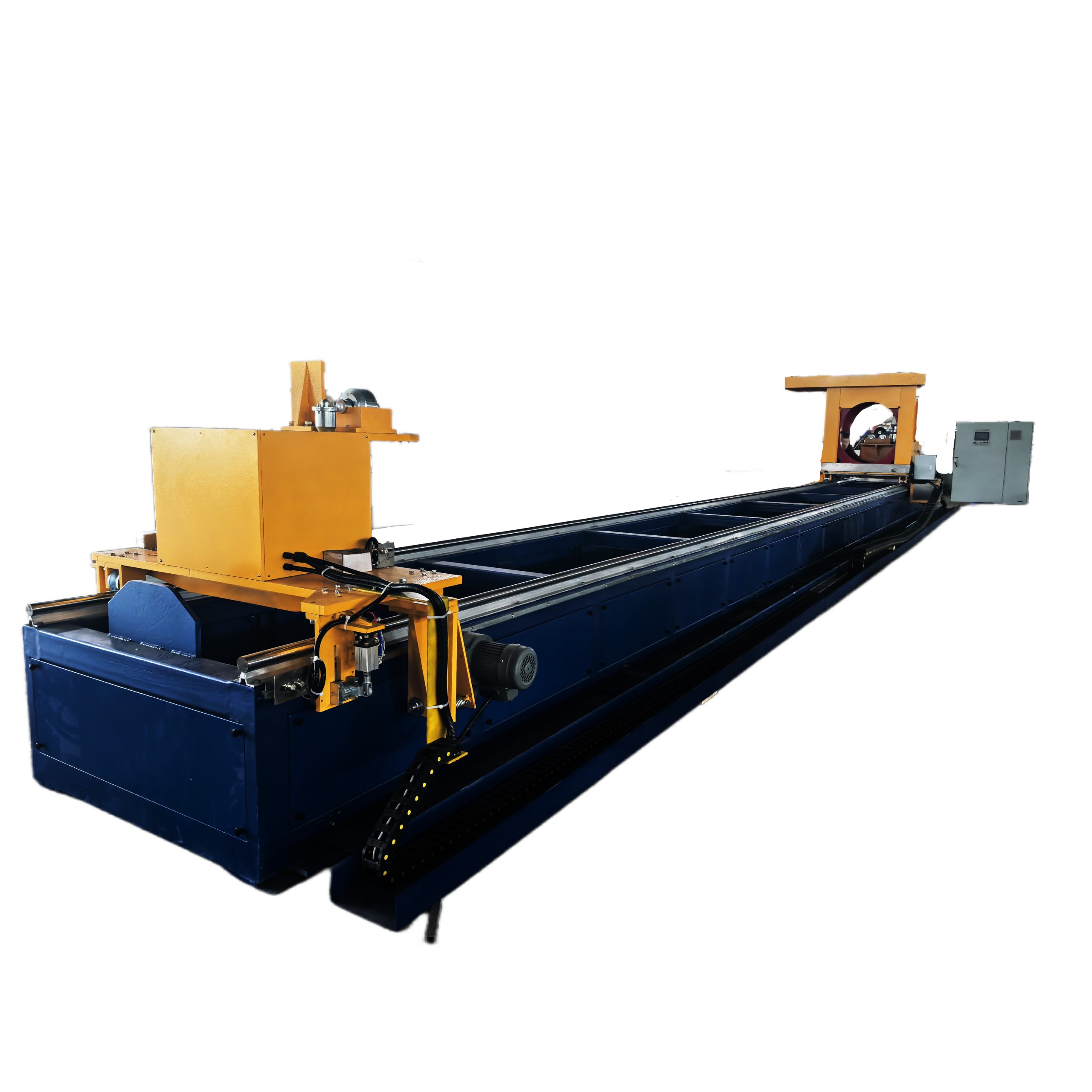

Nuke Non – Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle flaw detectors, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.