The AC/DC Fluorescent Magnetic Particle Inspection (MPI) Machine is widely applied across industries that require high-sensitivity detection of surface and near-surface defects in ferromagnetic materials. Its versatility, precision, and adaptability make it ideal for both production lines and maintenance environments.

1. Automotive Manufacturing

Used for inspecting:

-

Crankshafts, camshafts, gears, axles, and suspension parts

-

Detects fatigue cracks and grinding burns in high-stress components

-

Ensures compliance with international automotive quality standards (e.g., IATF 16949)

2. Aerospace and Aviation

Applied in:

-

Aircraft fasteners, turbine shafts, and landing gear parts

-

Critical for identifying tiny cracks that could lead to catastrophic failure

-

Meets stringent aerospace NDT regulations (e.g., NADCAP, AS9100)

3. Railway and Transportation

Inspection of:

-

Wheel axles, couplers, and bogie components

-

Enhances passenger safety and minimizes maintenance-related failures

-

Suitable for high-throughput inspection of mass transit parts

4. Oil & Gas / Energy Sector

Used for:

-

Drill pipes, casing ends, turbine blades, and generator shafts

-

Prevents equipment failure in high-pressure, high-temperature environments

-

Ensures the reliability of energy transmission and extraction systems

5. Heavy Equipment and General Manufacturing

Ideal for:

-

Forgings, castings, and machined parts in construction or industrial machines

-

Detects discontinuities that could compromise performance under heavy loads

-

Reduces the risk of warranty claims or field failures

6. Marine and Shipbuilding Industry

Applied to:

-

Propeller shafts, winches, engine blocks, and anchor systems

-

Provides corrosion-resistant testing methods for harsh environments

-

Ensures component durability and long-term reliability

The AC/DC MPI machine supports both manual and semi-automatic insp

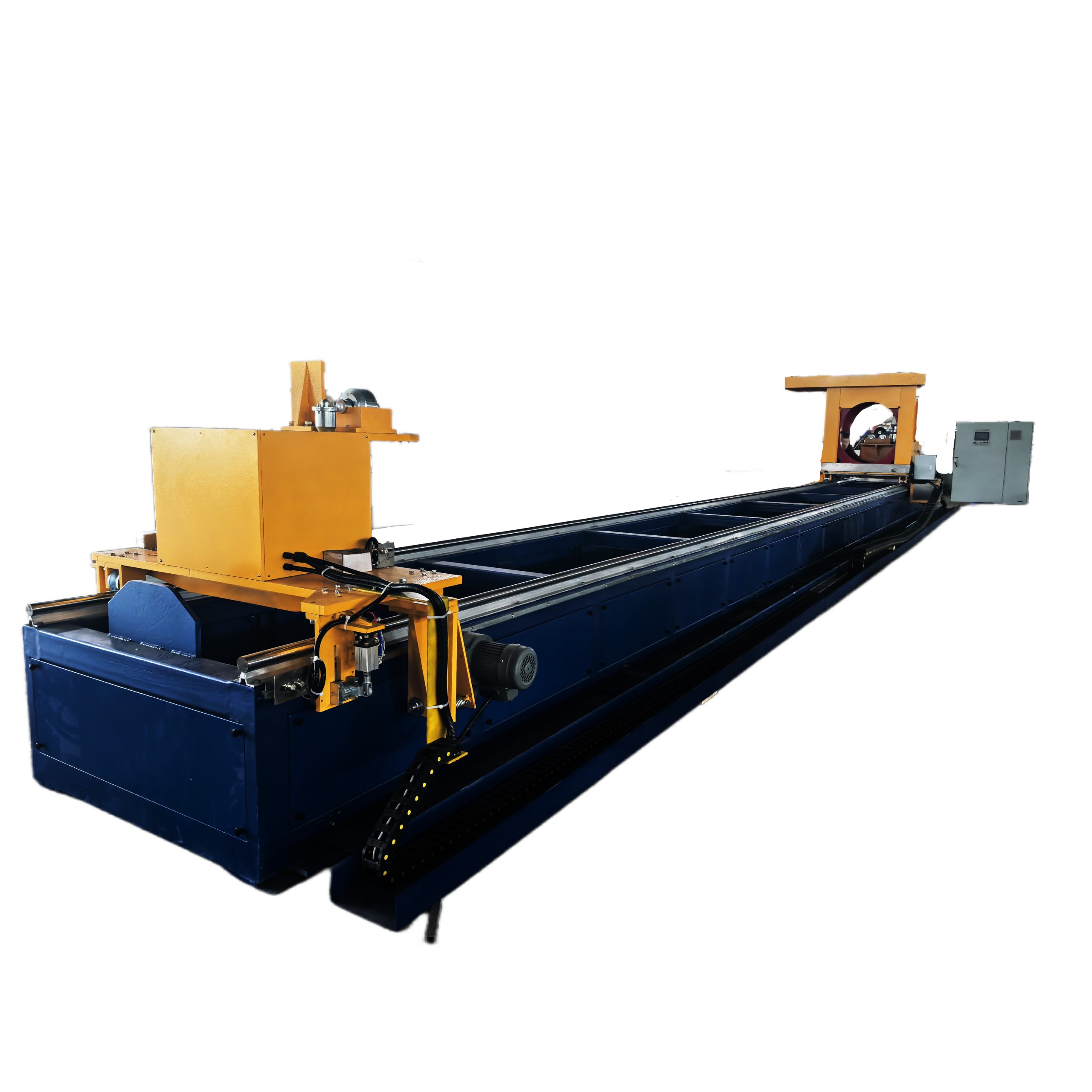

AC/DC Fluorescent Magnetic Particle Inspection Machine Flaw Detector

Nuke Non–Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.