OCTG Pipe End Inspection Using Magnetic Particle Testing

In the oil and gas industry, Oil Country Tubular Goods (OCTG) such as tubing and casing operate under extreme pressure, temperature, and corrosive conditions. Among all sections of an OCTG product, pipe ends and couplings are the most critical and failure-prone areas. For this reason, OCTG pipe end inspection has become a mandatory quality-control process for manufacturers, processors, and oilfield service companies worldwide.

What Is OCTG Pipe End Inspection?

OCTG pipe end inspection refers to non-destructive testing focused on the ends of tubing, casing, and couplings, particularly areas with complex geometry and high stress concentration. Typical inspection zones include:

-

Internal and external surfaces of couplings

-

Thread roots and thread flanks

-

Chamfered edges and transition zones

-

Connection areas between pipe body and coupling

The primary objective is to detect surface and near-surface discontinuities before the products are delivered or installed downhole.

Compared with the pipe body, pipe ends and couplings present several inherent risks:

-

High stress concentration caused by threading and make-up torque

-

Complex geometry that increases the likelihood of cracks and laps

-

Severe consequences of failure, including leaks, connection separation, or well shutdown

Even microscopic cracks at the coupling or thread root can propagate rapidly under cyclic loading. Therefore, oil and gas standards increasingly require 100% inspection of OCTG pipe ends, especially for export and premium-grade applications.

Why Magnetic Particle Testing Is Critical for OCTG Ends

Magnetic Particle Inspection (MPI) is widely recognized as the most effective method for inspecting ferromagnetic OCTG components, particularly pipe ends and couplings.

Key advantages of MPI include:

-

High sensitivity to surface and near-surface cracks

-

Excellent performance on threaded and irregular surfaces

-

Fast inspection cycle suitable for high-volume production

-

Compatibility with wet fluorescent magnetic particles for enhanced detection

As a result, MPI has become the industry-standard solution for OCTG pipe end inspection.

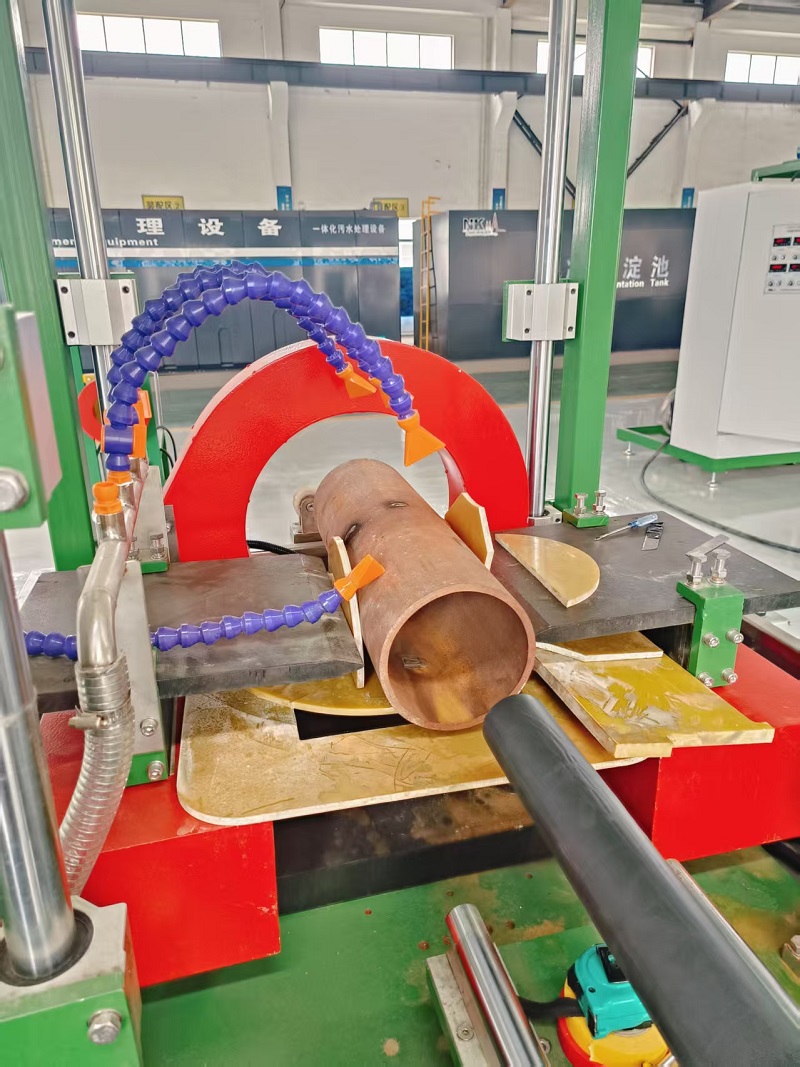

Typical Magnetization Techniques for Couplings

To ensure full defect coverage, multiple magnetization methods are commonly combined:

-

Central conductor magnetization for internal surfaces and thread roots

-

Coil magnetization for external surfaces and end faces

A properly designed MPI system ensures complete inspection of both internal and external coupling surfaces.

A professional OCTG pipe end inspection system should meet the following criteria:

-

Wide size coverage, typically from 2⅜” to 13⅜” or larger

-

Stable wet fluorescent MPI system with consistent particle suspension

-

Sufficient magnetizing power for varying wall thicknesses

-

Compliance with international standards such as ASTM and API

-

Semi-automatic or automatic operation to improve repeatability and reduce operator dependency

These requirements are especially critical for coupling manufacturers and OCTG processing lines serving international oil companies.

Industry Value of Proper OCTG Pipe End Inspection

Implementing a reliable OCTG pipe end MPI process delivers measurable benefits:

-

Reduced risk of downhole failures

-

Improved reliability of threaded connections

-

Compliance with oilfield acceptance and export requirements

-

Enhanced product credibility and brand reputation

For OCTG manufacturers, service companies, and third-party inspection providers, investing in dedicated pipe end MPI equipment is no longer optional—it is a competitive necessity.

With years of hands-on experience in designing and manufacturing OCTG pipe end magnetic particle inspection systems, our team has delivered customized MPI solutions for coupling and pipe-end testing lines across different oilfield standards and production requirements. Our equipment has been successfully exported to Indonesia, where it is used by local OCTG processors and inspection service providers to meet demanding oil and gas project specifications. This practical field experience allows us to optimize system reliability, inspection efficiency, and long-term operational stability.

As oil and gas operations continue to move toward deeper, hotter, and more demanding environments, OCTG pipe end inspection plays a decisive role in ensuring operational safety. Among available non-destructive testing methods, wet fluorescent Magnetic Particle Inspection stands out as the most reliable and efficient solution for coupling and pipe end testing.

Selecting the right MPI inspection system is not only a quality decision—it is a long-term investment in well integrity and operational reliability.

Find more solutions of OCTG pipe end inspection using magnetic particle testing, contact us.