Nuke NDT shipped MPI for Train Axle and wheelset inspection systems to Canada — reliable railway NDT gear with local support and easy commissioning.

Nuke NDT recently shipped an MPI for Train Axle and a complete wheelset inspection system to a maintenance workshop in Canada. We built these units to do one simple thing well: find cracks before they become failures.

We’re a big team with two decades in NDT. Over the years we’ve focused on practical machines — ones that are easy to use on a busy shop floor and hard to break. For this order we supplied:

-

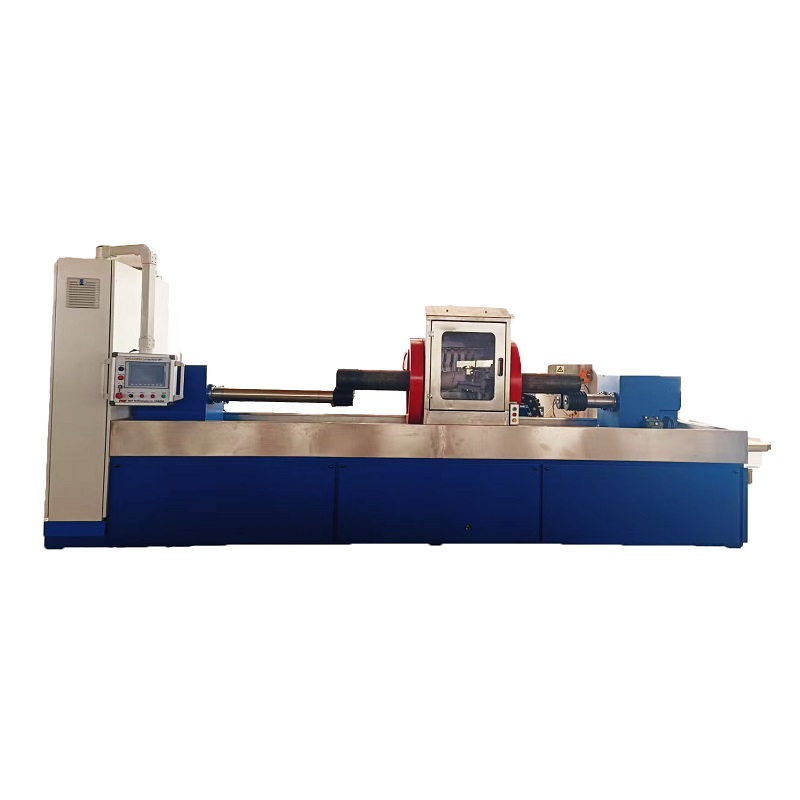

an MPI for Train Axle with automatic magnetization and demagnetization cycles,

-

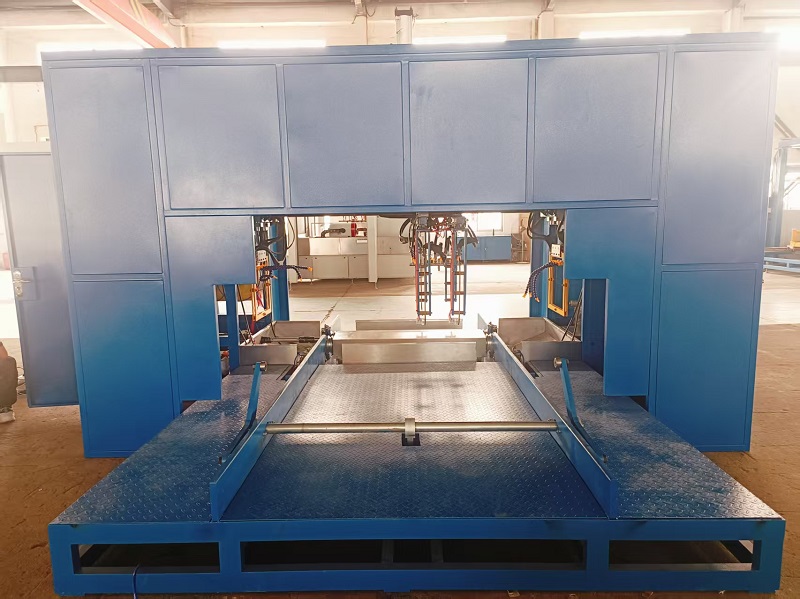

a wheelset MPI line that inspects entire assemblies without extra handling, and

-

a control console with a plain, operator-friendly interface.

Packing and shipping were handled with extra care so the equipment arrives ready to run. Our commissioning package includes remote setup help and operator training — we don’t just drop off the gear and disappear. If anything needs fine tuning once it’s on site, our engineers are a quick call away.

Why customers choose our MPI for Train Axle systems: they’re robust, they repeat results, and they’re built with real-world maintenance workflows in mind. We tune each system to the customer’s parts, so you get a reliable inspection process instead of a generic “one size fits all” solution.

If you’d like specifications, proposal, or a short demo video of a similar machine in use, contact Irene at irene@nksmartmeter.com or use the inquiry form on this page. We’ll reply with exact drawings, testing parameters, and lead times.