7 Essential Magnetic Particle Types for Flawless Testing: A Powerful Guide

Magnetic particle testing (MPT), also known as magnetic particle inspection, is a highly effective non-destructive testing method for detecting surface and near-surface defects in ferromagnetic materials. The success of MPT hinges on selecting the right magnetic particles, which are engineered to reveal leakage magnetic fields at material discontinuities. This article dives into the seven key types and properties of magnetic particles, optimized for those searching for “magnetic particle” insights, ensuring you achieve flawless inspection results.

What Are Magnetic Particles?

Magnetic particles are specialized ferromagnetic powders designed to highlight defects during MPT. Available in various sizes, shapes, and colors, these particles boast high magnetic permeability, enabling clear visualization of defect size and location. Choosing the right magnetic particles is critical for reliable, high-quality inspections.

7 Types of Magnetic Particles

Magnetic particles are categorized into non-fluorescent, fluorescent, and specialized types, each tailored for specific applications. Here are the seven essential types:

1. Non-Fluorescent Dry Powder

Used under visible light, these particles come in colors like black, reddish-brown, gray, blue, or white. Composed of iron oxides (Fe₃O₄ or Fe₂O₃) and dyed for visibility, they are ideal for dry method inspections, offering versatility across various workpieces.

2. Non-Fluorescent Wet Powder

Formulated for wet method inspections, these particles are mixed with oil or water to create a magnetic suspension. They provide enhanced sensitivity for detecting fine surface defects, making them a go-to choice for precision testing.

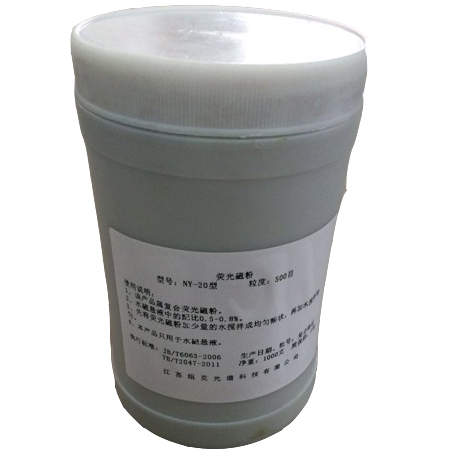

3. Fluorescent Magnetic Particles

Designed for UV light inspections, fluorescent particles emit bright yellow-green fluorescence (510–550 nm) when exposed to UV light. Made from magnetic iron oxide or carbonyl iron powder coated with fluorescent dye resin, they offer superior sensitivity and contrast, perfect for detecting minute defects quickly.

4. High-Temperature Magnetic Particles

These specialized non-fluorescent particles withstand temperatures of several hundred degrees Celsius, ensuring reliable performance in extreme environments like high-heat industrial settings.

5. Fixed Magnetic Particles

Formulated to adhere to workpieces for extended periods, these non-fluorescent particles are ideal for applications requiring long-term defect visibility, such as post-inspection analysis.

6. Magnetic Paste

A wet method variant, magnetic paste is a pre-mixed, concentrated form of magnetic particles that requires dilution before use. It simplifies preparation while maintaining high sensitivity for wet inspections.

7. Concentrated Magnetic Suspension

This ready-to-dilute suspension offers convenience for wet method testing, ensuring consistent particle distribution and high defect detection accuracy.

Key Properties of Magnetic Particles

The performance of magnetic particles depends on six critical properties: magnetism, particle size, shape, flowability, density, and visibility. Fluorescent particles also require stable fluorescent coatings.

1. Magnetism

Magnetism determines how particles respond to leakage magnetic fields. Ideal particles feature:

- High Magnetic Permeability: Ensures attraction to weak fields.

- Low Remanence and Coercivity: Prevents clumping, maintaining mobility and reducing background noise.

Excessive remanence can cause particle aggregation, lowering contrast and clogging wet method equipment.

2. Particle Size

Particle size impacts suspension stability and defect detection:

- Fine Particles (1–10 µm): Best for surface defects in wet methods, offering clear indications.

- Coarser Particles (10–50 µm): Ideal for subsurface defects in dry methods due to higher permeability.

- Fluorescent Particles: Range from 5–25 µm due to coatings.

- Dry Method Particles: Up to 150 µm to avoid dust-like adhesion.

Mixed sizes are often used for uniform sensitivity. Size is measured via microscopy, alcohol sedimentation, or sieving (80–160 mesh for dry, 300+ mesh for wet).

3. Shape

Particles vary from elongated (conical) to spherical or irregular. Elongated shapes magnetize easily for clear indications but have poor mobility. Spherical particles improve flowability. A mix balances both qualities.

4. Flowability

Flowability ensures particles move to defect sites. Wet methods rely on suspension flow, while dry methods use air currents and AC or half-wave rectified current to enhance movement. DC is avoided in dry methods due to poor flow.

5. Density

Density affects mobility and suspension stability. High-density iron oxide (~4.5 g/cm³) settles quickly, reducing sensitivity. Low-density hollow spherical particles (0.7–2.3 g/cm³) excel in wet methods.

6. Visibility

Visibility is key for defect identification:

- Non-Fluorescent Particles: Require strong color contrast with the workpiece.

- Fluorescent Particles: Emit vivid yellow-green light under UV, offering unmatched contrast on dark surfaces.

Fluorescent particles need stable coatings for consistent brightness.

Performance Testing and Acceptance

Magnetic particle performance is evaluated per standards like JB/T 6063–1992, focusing on magnetism, particle size, color, impurities, and suspension.

1. Magnetism Testing

Magnetism is tested using an electromagnet to attract particles from a suspension, ensuring no residue remains. Older methods like magnetic weighing are less common.

2. Particle Size and Suspension

Size is verified via sieving (85% pass rate), microscopy, or alcohol sedimentation (suspension height ≥180 mm in a 400 mm tube).

3. Defect Indication

Standard test blocks confirm clear defect indications under specified conditions, such as displaying five holes (DC) or one hole (AC).

4. Contamination

Suspensions are inspected after 30 minutes of settling to ensure no foreign matter or clumping.

5. Fluorescent Particle Testing

Additional checks include:

- Fluorescence Color: Yellow-green under UV (320–400 nm, ≥1000 µW/cm²).

- Contrast: Clear indications with minimal background fluorescence.

- Stability: Retained sensitivity, color, and brightness after stirring or two weeks of static suspension.

Choosing the Right Magnetic Particles

Select particles based on:

- Inspection Method: Fine particles for wet, coarser for dry.

- Defect Type: Fine for surface, coarser for subsurface.

- Fluorescent vs. Non-Fluorescent: Fluorescent for high sensitivity, non-fluorescent for cost or special cases.

- Environment: High-temperature or fixed particles for extreme conditions.

Conclusion

Magnetic particle testing is a powerful tool for detecting defects in ferromagnetic materials, and choosing from these seven essential magnetic particle types ensures flawless results. By understanding their properties and adhering to rigorous performance standards, inspectors can achieve unmatched accuracy and reliability. Whether using fluorescent particles for high sensitivity or specialized particles for unique conditions, the right choice drives superior defect detection.

For advanced non-destructive testing solutions, visit our website or contact us for expert guidance.