Fluorescent Magnetic Particle Inspection

1 Inspection Environment Requirements

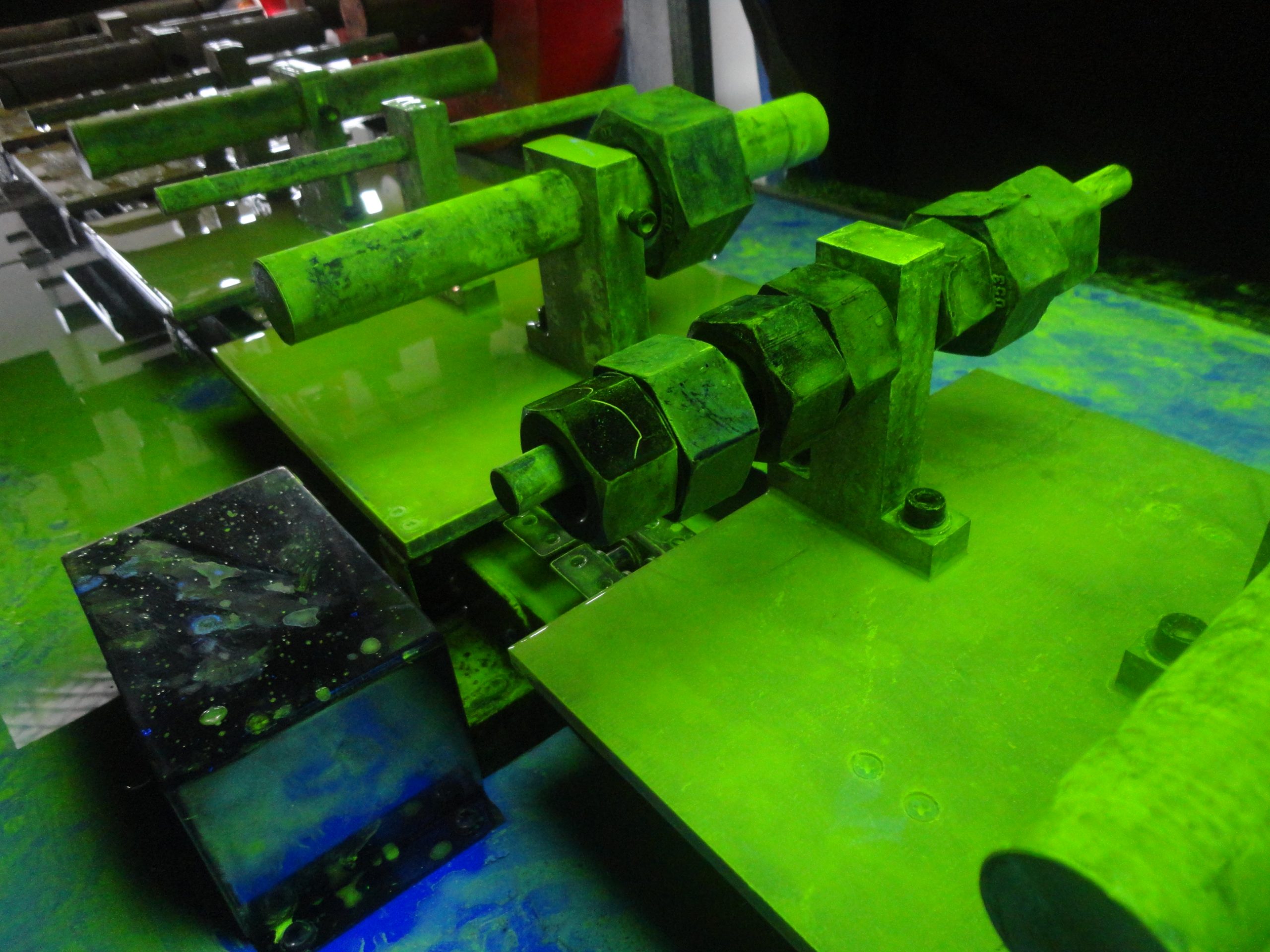

Fluorescent magnetic particles (also known as magnetic indications) form visible patterns on the surface of a workpiece. Observations must be conducted under standard lighting conditions. For non-fluorescent particles or suspensions, white light should be used, and the surface illumination must be at least 100 lux to detect fine surface defects clearly. When using fluorescent magnetic particles, observation must be done in a dark room or shaded environment with ultraviolet (UV) light.

The white light intensity in the observation area must not exceed 20 lux. The UV wavelength and intensity must meet relevant standards. Operators must allow their eyes 5 minutes to adapt to dark conditions before inspection.

UV Light Usage Tips:

- After ignition, UV lamps need about 5 minutes to reach full output.

- Avoid frequent switching to prolong lamp life.

- Measure UV intensity periodically due to degradation over time.

- Use a voltage stabilizer to ensure stable operation.

- Replace damaged or dirty filters promptly to maintain UV efficiency.

- Prevent magnetic suspension from splashing on the lamp.

- Never expose eyes directly to UV radiation.

2 Magnetic Indication Observation Method

Magnetic indications must be observed and evaluated promptly. In continuous magnetization methods, inspection can occur during or immediately after particle application. First, scan the entire test surface to understand the distribution. For large parts, divide into sections. For rotating parts, mark the starting point. Carefully handle parts to avoid smearing or losing indications.

Examine the shape and distribution of the indications and consider the manufacturing process for accurate defect identification. For unclear indications, re-magnetization or increasing current may help. A low-magnification glass (<5x) may also assist.

3 Understanding and Evaluating Material Discontinuities

Material discontinuities refer to structural changes that interrupt material uniformity, which may be natural or caused by processing errors. Defects include cracks, inclusions, folds, porosity, etc. Surface defects may be visible or near-surface, requiring magnification. It is critical to distinguish real defects from false or irrelevant indications.

Not all defects lead to rejection; evaluation must follow product-specific standards. Some flaws may be acceptable depending on the application. Accurate classification and assessment according to standards are essential.

4 Recording and Preserving Magnetic Indications

Indications must be documented, especially for critical areas. Methods include:

- Drawing a sketch with indication details.

- Adhesive tape transfer using a solvent-cleaned dry surface.

- Peelable film spraying to capture the indication.

- Rubber casting for internal or hard-to-access areas.

- Photography with scale for documentation.

- Inspection record sheets noting location, length, and count.

Maintain long-term records for reference and traceability.

5 Test Records and Inspection Reports

Test records must be filled out by inspectors and include:

- Workpiece name, dimensions, material, heat treatment, and surface condition

- Inspection equipment and conditions: magnetic powder type, magnetizing current/method, standard, etc.

- Defect details: indication size, location, classification, and evaluation standard used

- Other data: inspection date, location, inspector name, and qualification

Inspection reports are formal documents based on client requirements and must be signed by responsible personnel. Format and content should meet applicable standards.

Nuke Non–Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing and marketing service system, ensuring high efficiency and reliable product performance. With the aid of computer-aided design (CAD) and a professional technical team, our products are developed with precision and optimized for real-world industrial applications.

Our equipment is widely used in critical sectors where safety and quality are paramount, including:

-

Aerospace and Aviation

-

Military and Defense

-

Railways and Locomotive Manufacturing

-

Automotive and Motorcycle Production

-

Shipbuilding and Marine Engineering

-

Oilfield and Petrochemical Industry

-

Boilers and Pressure Vessels

-

Bearings, Gears, Springs, and Standard Parts Manufacturing

-

Diesel Engines, Tractors, and Agricultural Machinery

-

Power Generation and Chemical Processing

Driven by technological innovation and a commitment to customer satisfaction, Nuke continues to expand its presence both in domestic and international markets. With reliable quality, responsive service, and a strong reputation, we have earned the trust of partners across various industries.

At Nuke, we are committed to delivering intelligent, efficient, and practical NDT solutions to help our customers improve quality control and enhance operational safety.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.