In the fastener industry, ensuring product reliability and safety is paramount. Defects such as cracks, seams, or inclusions in fasteners can lead to catastrophic failures in critical applications. Magnetic Particle Inspection (MPI) machines offer a non-destructive testing (NDT) solution that efficiently detects surface and near-surface flaws in ferromagnetic materials. For fastener manufacturers and suppliers, investing in high-quality MPI equipment is essential to maintain stringent quality standards and meet industry regulations.

Why Magnetic Particle Inspection is Ideal for Fasteners

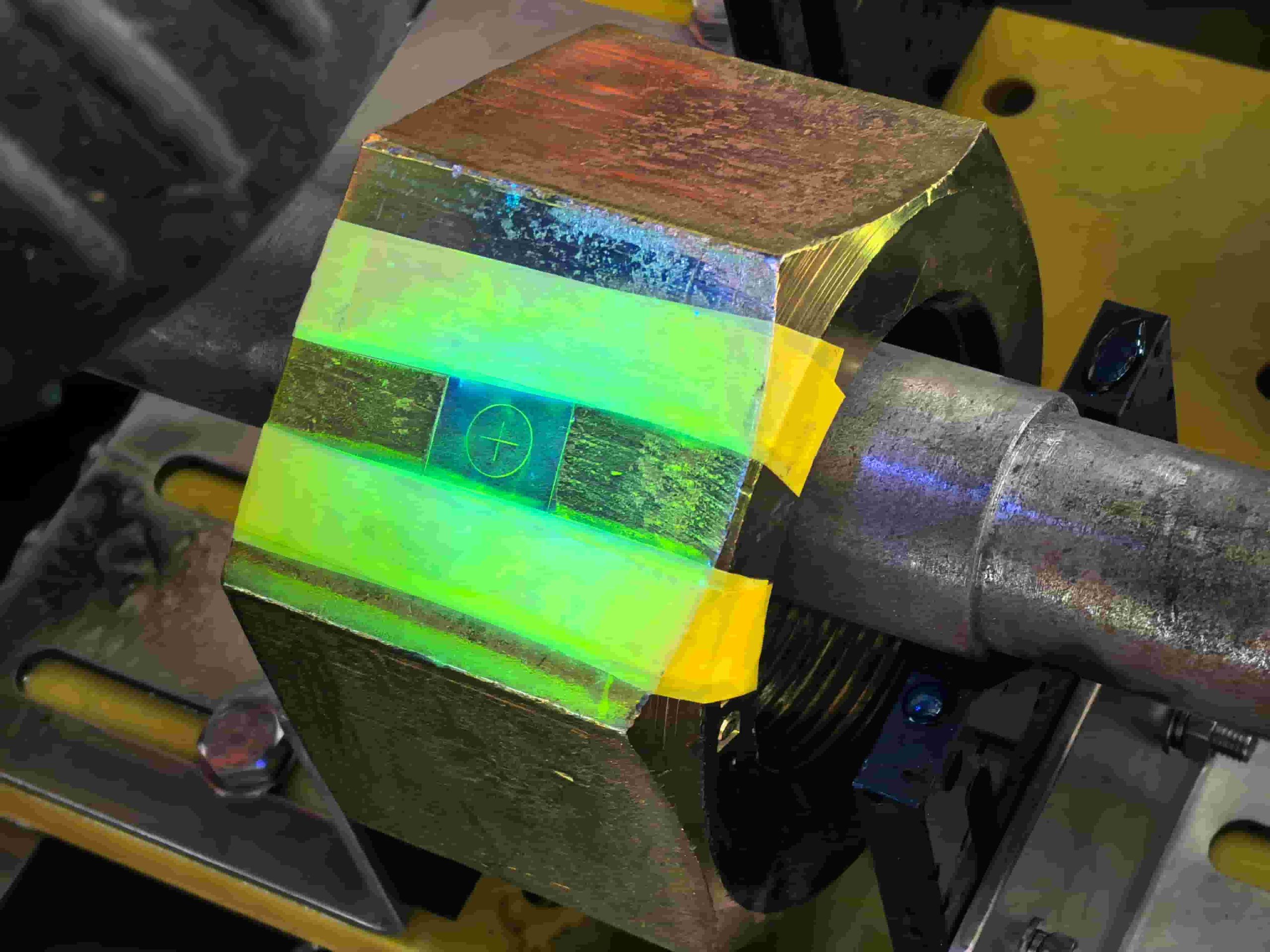

Magnetic Particle Inspection is widely recognized for its accuracy, speed, and cost-effectiveness in detecting discontinuities in ferromagnetic components like bolts, screws, nuts, and washers. By magnetizing the fastener and applying magnetic particles, any defects disrupt the magnetic field, forming visible indications. This process ensures:

-

High Detection Sensitivity: Identifies even the smallest surface and near-surface flaws.

-

Rapid Results: Allows for quick inspection, making it suitable for high-volume production environments.

-

Compliance with Standards: Meets international quality standards such as ISO, ASTM, and ASME.

Key Features of Modern MPI Machines for Fasteners

Today’s MPI machines are designed with advanced features to streamline the inspection process:

-

Automated Handling Systems: Ideal for inspecting large batches of fasteners with consistent accuracy.

-

Adjustable Magnetization Levels: Cater to various fastener sizes and materials.

-

UV/Black Light Technology: Enhances visibility of fluorescent magnetic particles for precise defect recognition.

-

User-Friendly Interfaces: Simplify operation and reduce training time.

-

Durable Construction: Built to withstand industrial environments and ensure long-term reliability.

Applications Across the Fastener Industry

MPI machines are used to inspect fasteners in numerous sectors, including:

-

Automotive: Ensuring the integrity of engine components, brake systems, and structural fasteners.

-

Aerospace: Verifying critical fasteners in aircraft assemblies and propulsion systems.

-

Construction: Checking bolts and anchors used in bridges, buildings, and infrastructure projects.

-

Oil and Gas: Inspecting fasteners in drilling equipment, pipelines, and valves.

Choosing the Right MPI Machine for Your Needs

Selecting the appropriate magnetic particle inspection equipment depends on factors such as production volume, fastener size, and specific application requirements. Whether you need a portable unit for on-site inspections or a fully automated system for factory integration, understanding your needs will help you maximize ROI and quality assurance.

Boost Your Fastener Quality with Our MPI Solutions

Our range of magnetic particle inspection machines is engineered to deliver unmatched precision and efficiency for fastener testing. With customizable options and expert support, we help you achieve zero-defect production and uphold the highest quality benchmarks.

Explore our MPI machines today to ensure the reliability and safety of your fasteners!