The CDW-24000AT Fluorescent Magnetic Particle Inspection Machine is a specialized solution for detecting surface and near-surface defects in cylindrical ferromagnetic components, especially gas cylinders. Its advanced performance and high adaptability make it suitable for a wide range of industries that require safe, reliable, and efficient non-destructive testing (NDT).

🔹 1. Gas Cylinder Manufacturing Industry

This is the primary application field of the CDW-24000AT. The machine is widely used for:

In gas cylinder production, fluorescent magnetic particle inspection ensures there are no cracks, laps, or other defects in the body or shoulder area of the cylinder, which is critical for pressure resistance and safety compliance.

✅ Key benefit: Ensures structural integrity before delivery or filling.

🔹 2. Firefighting Equipment Manufacturers

Manufacturers of:

must conduct strict NDT testing. The CDW-24000AT provides high sensitivity and full coverage of the curved cylinder surface, ensuring safety for emergency applications.

✅ Key benefit: Prevents hidden defects that could lead to failure under pressure during emergencies.

🔹 3. Pressure Vessel Re-certification & Cylinder Testing Centers

In many countries, gas cylinders must undergo periodic inspection and re-certification. The CDW-24000AT is ideal for third-party inspection agencies, testing centers, and government-certified NDT labs, offering fast throughput and reliable results.

✅ Key benefit: Speeds up high-volume inspection while maintaining strict compliance.

🔹 4. Oil & Gas and Petrochemical Industry

On-site storage and transport of gases like propane, acetylene, and hydrogen often require cylinder integrity assurance. The CDW-24000AT supports in-house quality checks for:

✅ Key benefit: Reduces downtime and ensures safety in explosive or corrosive environments.

🔹 5. Aerospace and Defense

In the aerospace and defense industries, portable gas cylinders are used in:

-

Aircraft oxygen supply systems

-

Escape slide inflation systems

-

Military breathing apparatus and ground support units

These critical systems demand flawless cylinders, and magnetic particle testing is an essential step in their validation process.

✅ Key benefit: Enhances flight safety and defense equipment reliability.

🔹 6. Industrial Gas Distribution

Gas suppliers dealing in:

can use this machine for incoming or outgoing cylinder quality inspection, helping maintain their reputation for safety and reliability.

✅ Key benefit: Prevents field failures and strengthens customer trust.

🏷️ Summary

The CDW-24000AT is not limited to a single industry — it plays a vital role wherever gas cylinders and high-pressure vessels are manufactured, certified, or used. Its versatility, precision, and automation make it a valuable asset across industries focused on pressure equipment safety and non-destructive evaluation.

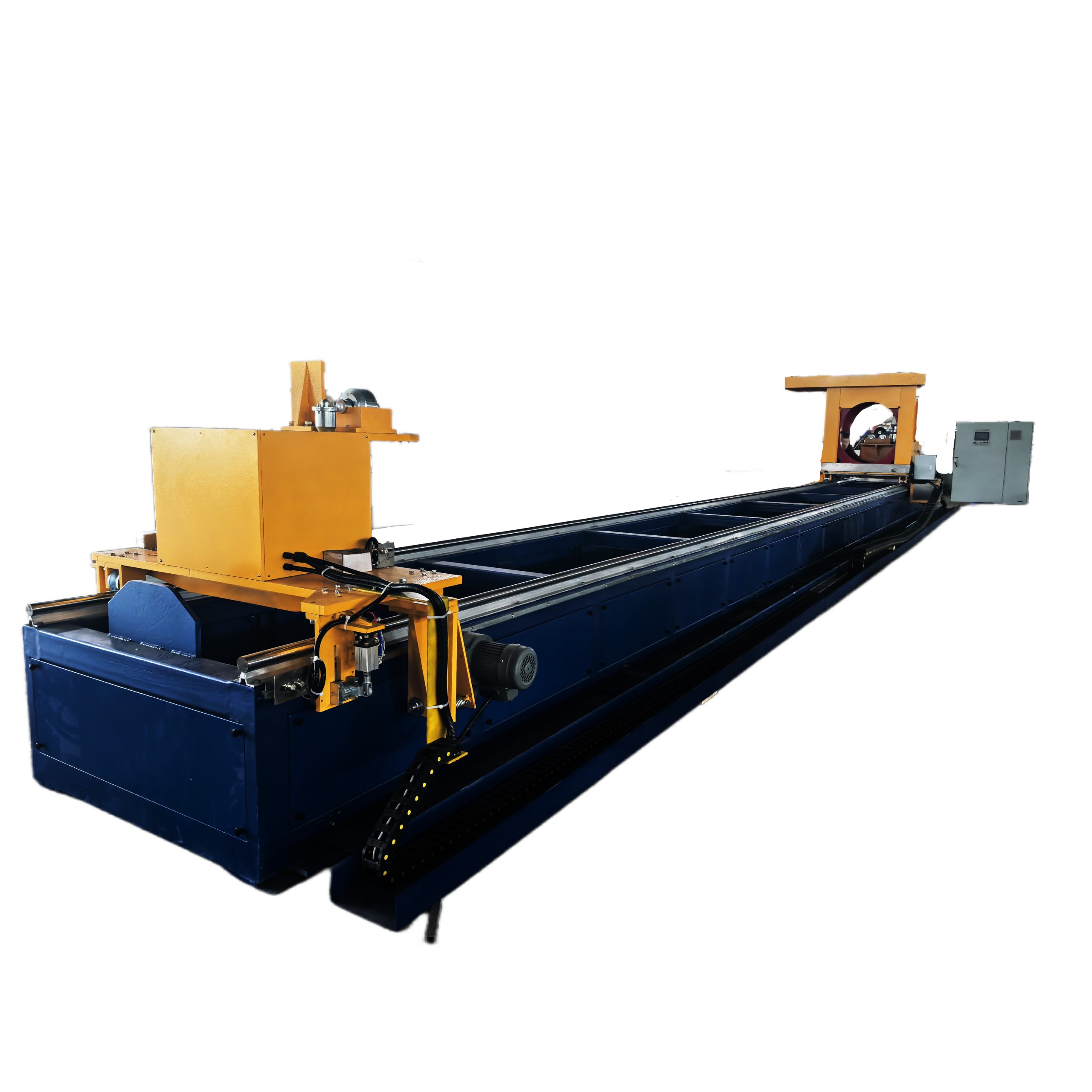

CDW-24000AT Fluorescent Magnetic Particle Testing Machine for Gas Cylinders

Nuke Non–Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing and marketing service system, ensuring high efficiency and reliable product performance. With the aid of computer-aided design (CAD) and a professional technical team, our products are developed with precision and optimized for real-world industrial applications.

Our equipment is widely used in critical sectors where safety and quality are paramount, including:

-

Aerospace and Aviation

-

Military and Defense

-

Railways and Locomotive Manufacturing

-

Automotive and Motorcycle Production

-

Shipbuilding and Marine Engineering

-

Oilfield and Petrochemical Industry

-

Boilers and Pressure Vessels

-

Bearings, Gears, Springs, and Standard Parts Manufacturing

-

Diesel Engines, Tractors, and Agricultural Machinery

-

Power Generation and Chemical Processing

Driven by technological innovation and a commitment to customer satisfaction, Nuke continues to expand its presence both in domestic and international markets. With reliable quality, responsive service, and a strong reputation, we have earned the trust of partners across various industries.

At Nuke, we are committed to delivering intelligent, efficient, and practical NDT solutions to help our customers improve quality control and enhance operational safety.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.