Students from Peking University’s College of Engineering visited our company to gain hands-on experience in non destructive testing magnetic particle inspection systems. See how the visit unfolded.

Non Destructive Testing Magnetic Particle Inspection: Peking University Engineering Students Visit Our Facility

Non destructive testing magnetic particle inspection is an essential technology across critical industries—and this Wednesday, it took center stage as we welcomed students from the College of Engineering at Peking University to our manufacturing facility for a full-day technical visit.

As a leading manufacturer of high-precision non destructive testing (NDT) equipment, including magnetic particle inspection systems, we are committed to nurturing future engineers and contributing to industry-academic collaboration. This visit was an exceptional opportunity for top students from China’s most prestigious university to gain real-world experience and understand the role of NDT in modern industrial applications.

The visit kicked off with a comprehensive company presentation, where our team introduced our main product lines, development history, and global market reach. The focus quickly shifted to our expertise in non destructive testing magnetic particle inspection—a method used to detect surface and near-surface flaws in ferromagnetic materials without damaging the components.

Our engineers explained how magnetic fields and fine magnetic particles are used in this process, offering high sensitivity for detecting cracks, seams, and other discontinuities. The students were particularly engaged when learning about our automated MPI lines, portable units, demagnetizers, and advanced UV inspection stations.

The group was then taken on a guided tour through our production workshop. They witnessed every stage of MPI equipment manufacturing—from structural assembly and circuit integration to calibration, testing, and final quality assurance. A live demonstration of fluorescent magnetic particle inspection techniques showcased how even micro-sized cracks can be revealed under UV light when proper inspection materials are used.

Throughout the demonstration, our experts discussed the critical importance of MPI in aerospace, automotive, petrochemical, and railway industries. Many students expressed surprise at how commonly non destructive testing magnetic particle inspection is applied to components such as crankshafts, gears, axles, turbine blades, and welding seams.

In a discussion forum after the tour, students asked detailed questions regarding MPI sensitivity levels, testing standards, and how automation and digitalization are transforming the future of NDT. Our R&D engineers also introduced our latest developments in intelligent defect recognition and reporting systems.

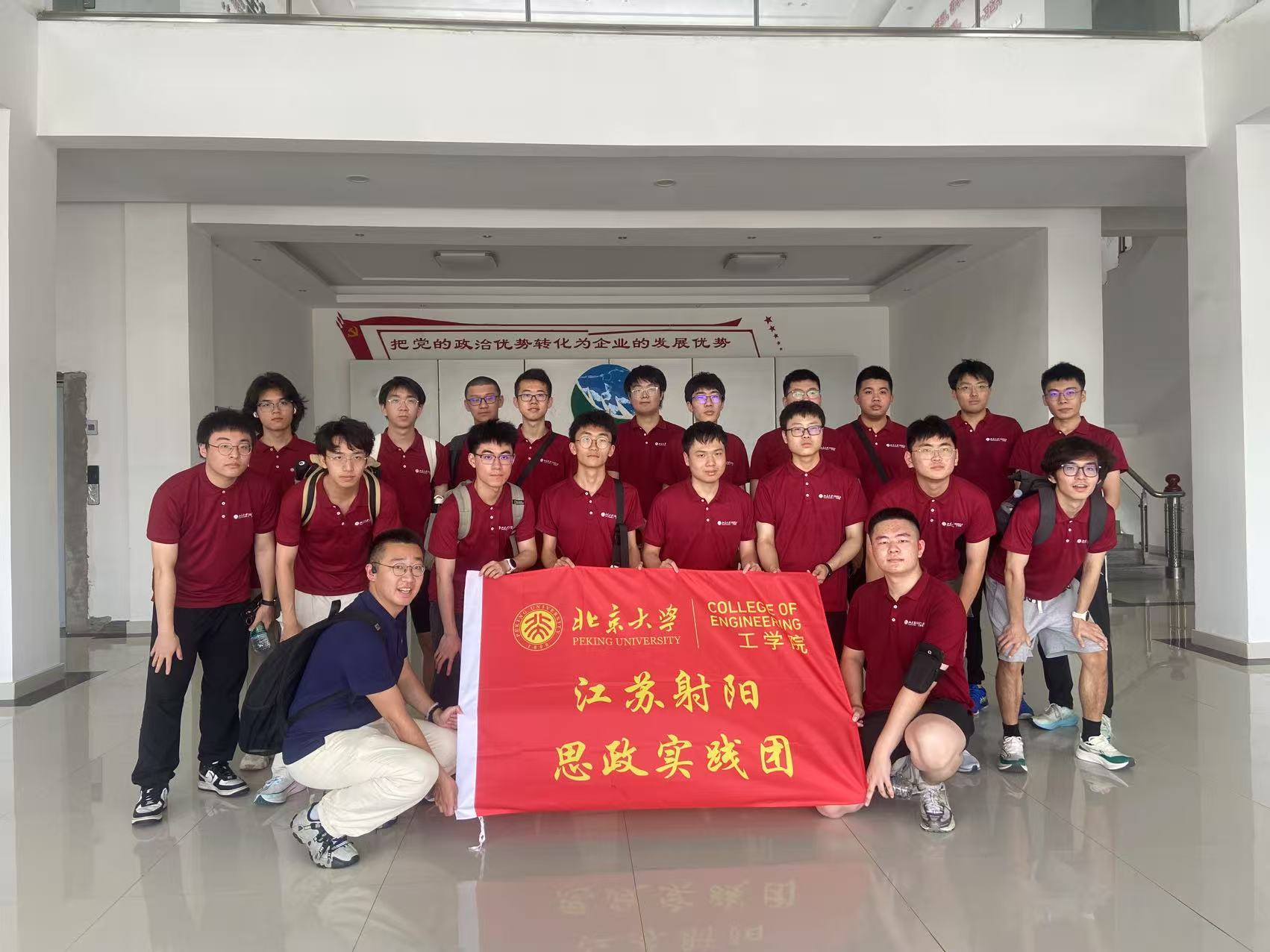

The visit concluded with group photos and a roundtable discussion about future internships and potential collaboration between our company and Peking University. The feedback we received was overwhelmingly positive, with students appreciating the hands-on experience and the clear explanation of complex testing principles.

At Nuke NDT, we strongly believe that fostering young talent and promoting awareness of non destructive testing magnetic particle inspection is vital to industry growth and technological innovation. We are proud to support educational programs that encourage students to explore the science behind quality assurance and safety-critical inspections.

We extend our sincere thanks to the faculty and students of Peking University for this meaningful exchange. We look forward to future collaboration and to inspiring the next generation of engineers in the world of non destructive testing.