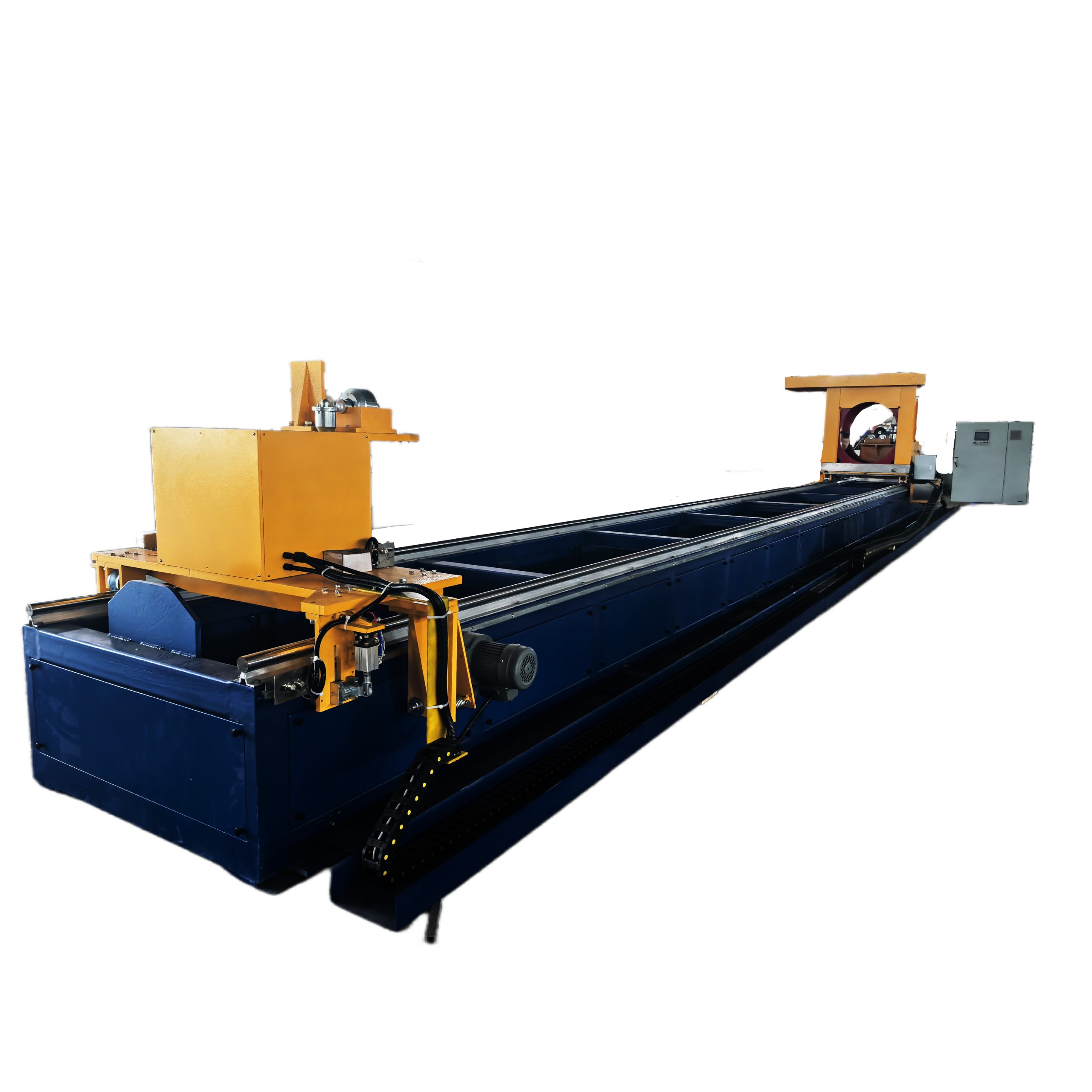

The CNK-8000 Magnetic Particle Inspection Machine for Sun Gear is engineered for high-precision non-destructive testing (NDT) of gear-related components. Its advanced magnetic particle technology makes it ideal for industries that demand high-quality flaw detection on ferromagnetic parts with complex geometries.

✅ 1. Automotive Industry

Used extensively in car transmission systems, this machine inspects sun gears, planetary gears, and spline shafts found in automatic and manual gearboxes. It ensures early detection of cracks or surface defects to prevent failure during operation.

✅ 2. Aerospace Industry

In aerospace applications, even microscopic flaws can lead to critical failures. The CNK-8000 is ideal for testing precision gear assemblies in turbines, landing gear systems, and aerospace actuators.

✅ 3. Heavy Machinery and Industrial Equipment

Large industrial gear components in construction equipment, mining machines, and hydraulic systems require thorough flaw detection. This machine ensures safe operation and extended service life of these parts.

✅ 4. Wind Power and Energy Sector

Used for detecting defects in wind turbine gearboxes and rotor drive systems, helping to reduce downtime and ensure uninterrupted energy production.

✅ 5. Railway and Marine Engineering

The machine is suitable for inspecting gear components in locomotive systems, gear couplings, and marine propulsion mechanisms, where mechanical integrity is essential for safety and performance.

With its specialized structure and reliable detection accuracy, the CNK-8000 Magnetic Particle Inspection Machine for Sun Gear brings value across multiple sectors where gear performance and structural integrity are mission-critical.

🔗 Explore more NDT Equipment for Gear Component Testing and Industry-Specific Magnetic Particle Inspection Solutions.

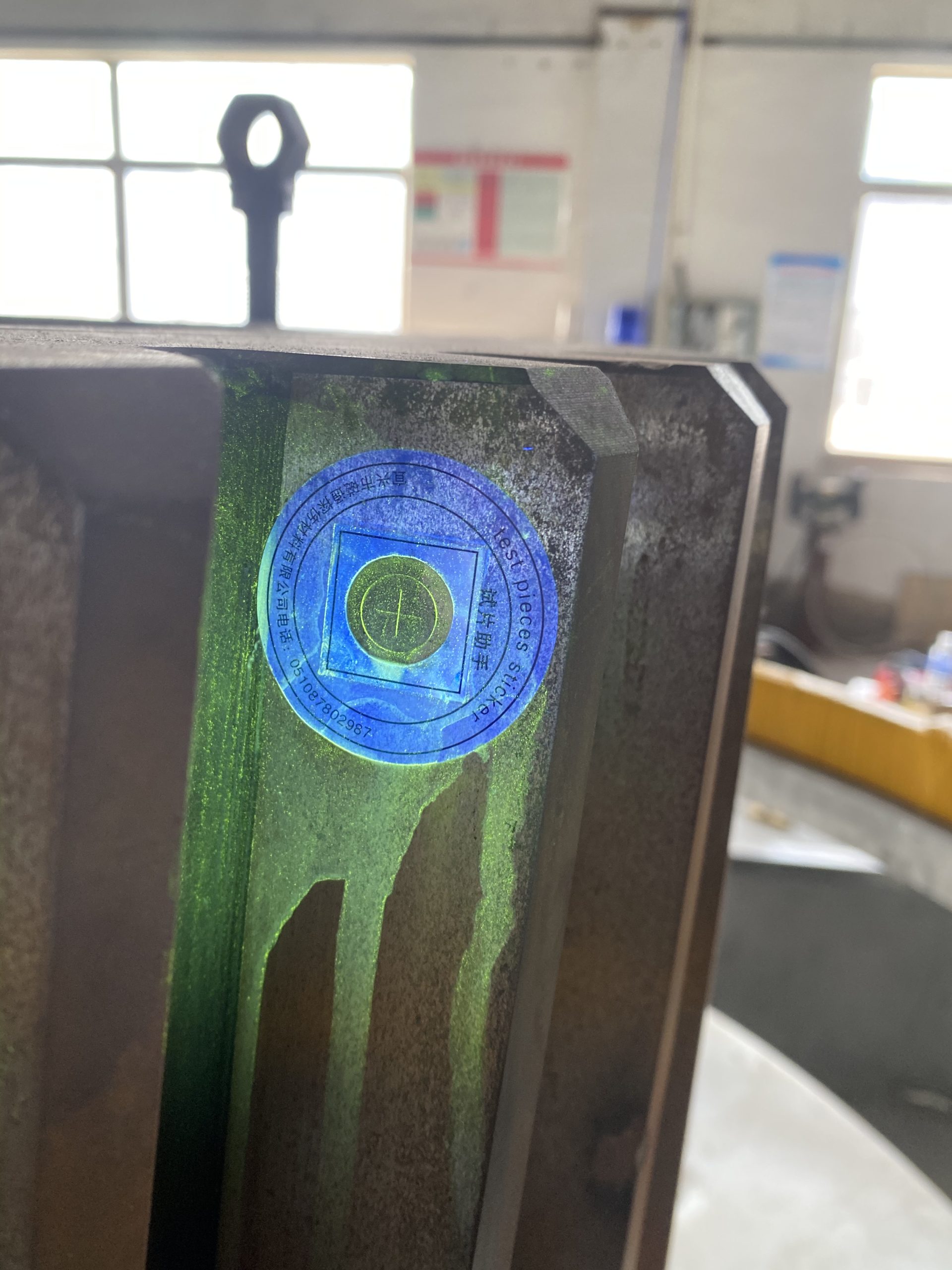

CNK8000 Fluorescent Magnetic Particle Inspection Machine for Sun Gear, Planet Gear & Spline Shaft

Nuke Non–Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.