Application Fields

The Semi-Automatic Magnetic Particle Inspection Machine for Bearing Rings is widely used in industries where high-precision, non-destructive testing (NDT) is critical to ensure product reliability and safety. Below are the major application fields:

🔧 1. Bearing Manufacturing Industry

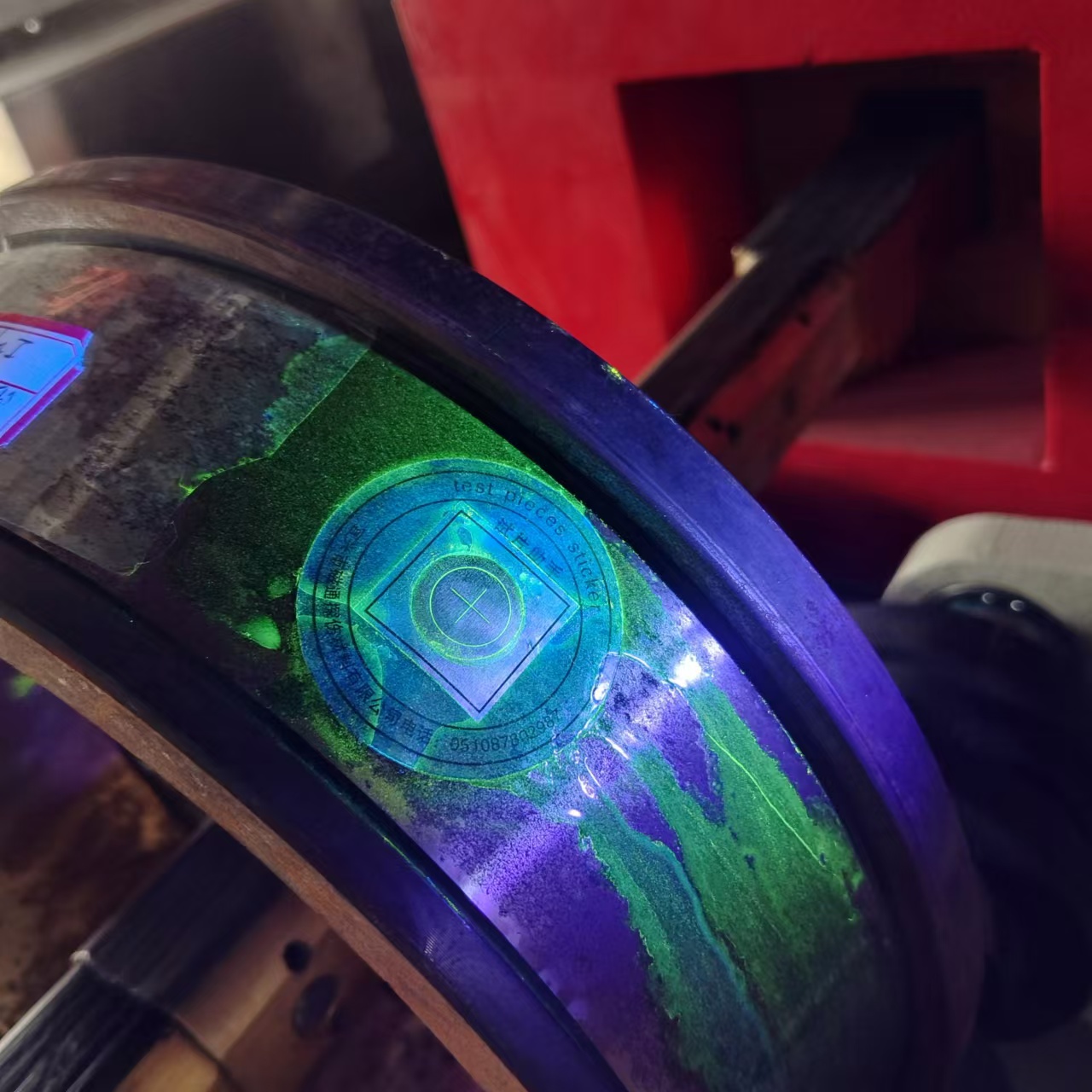

Used to detect surface and subsurface cracks in tapered, cylindrical, and spherical roller bearing rings during production and quality control processes.

🚗 2. Automotive Industry

Applied in the inspection of automotive bearing components, ensuring their structural integrity before assembly in engines, wheels, transmissions, and suspension systems.

✈️ 3. Aerospace Industry

Used to inspect aircraft bearing rings and other critical rotating parts that must comply with strict safety standards, such as NAS 410 and EN 4179.

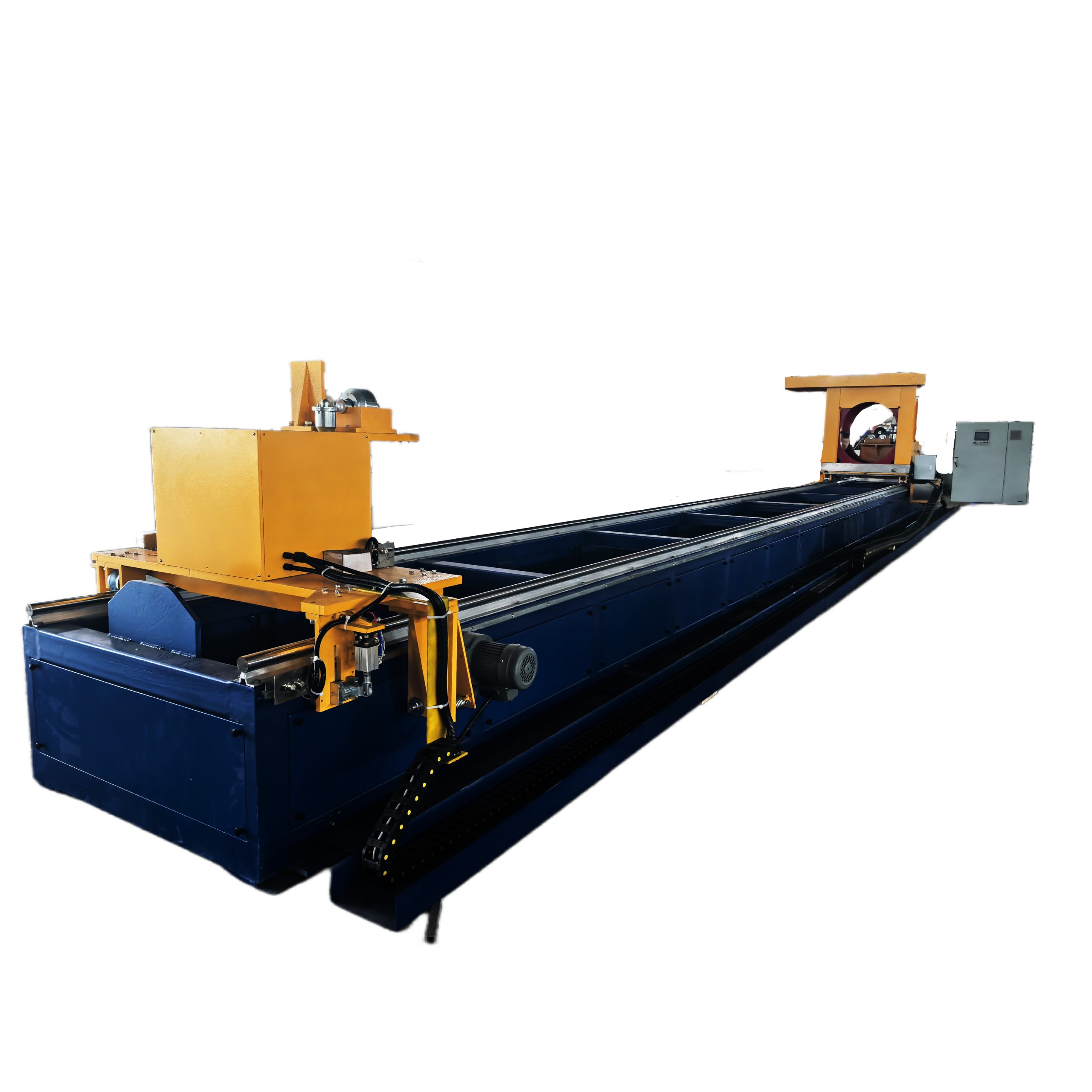

⚙️ 4. Heavy Machinery and Industrial Equipment

Ideal for inspecting large bearing components in equipment such as turbines, gearboxes, presses, and rotating shafts, helping prevent mechanical failure in high-load applications.

🏭 5. Railways and Wind Energy Sector

Ensures the quality of bearing parts used in high-speed rail and wind turbines, where long-term reliability is essential under dynamic operating conditions.

This machine provides accurate and reliable flaw detection, helping customers reduce the risk of equipment failure, improve product quality, and comply with international testing standards.

🔗 Explore our full range of NDT Equipment for Bearing Inspection and discover industry-specific solutions.

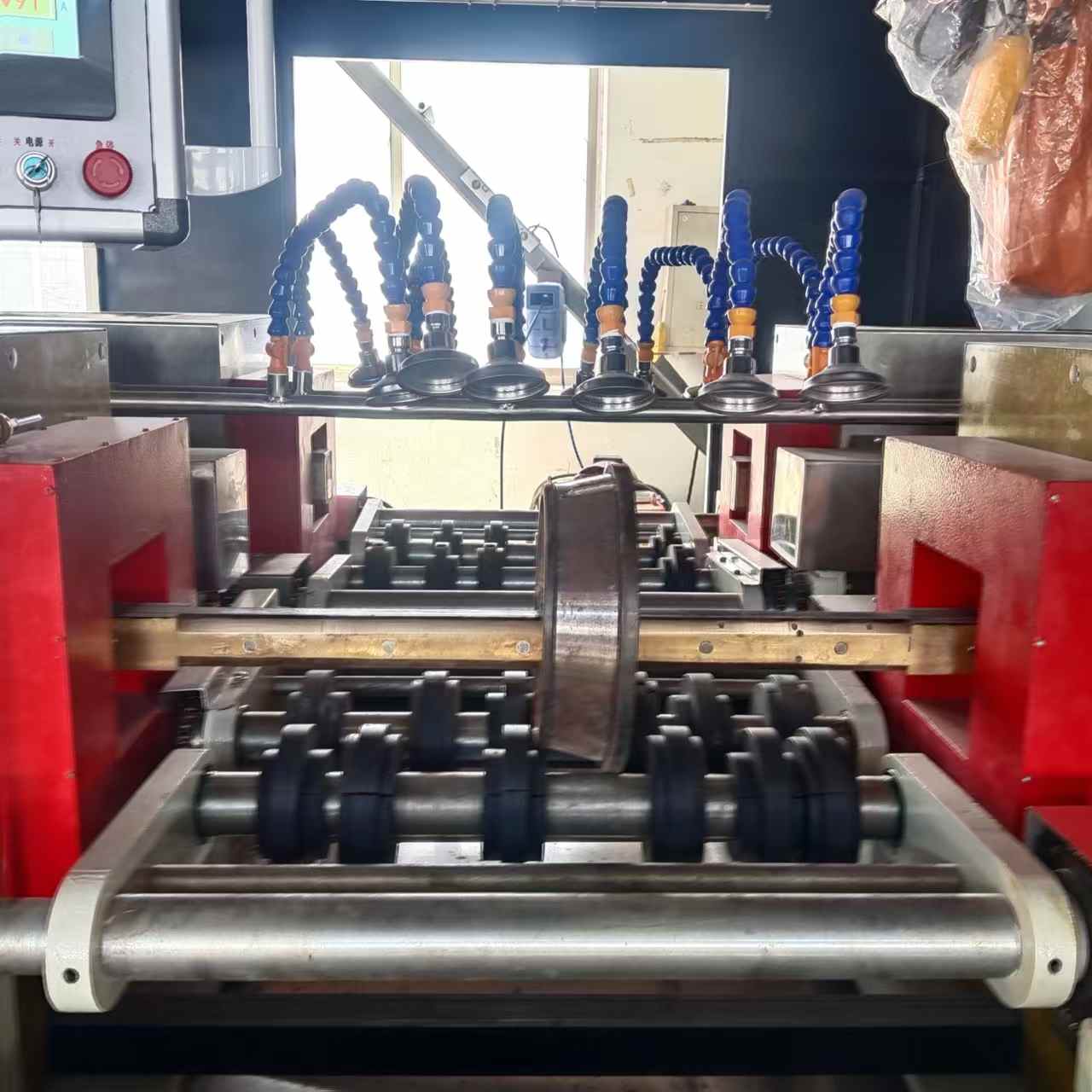

CNX9000 Fluorescent Magnetic Particle Flaw Detector for Bearing Components CE Certified

Nuke Non–Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.