The Semi-Automatic Fluorescent Penetrant Inspection Line is widely used across various industries that demand precise and reliable surface defect detection. Its versatility and high sensitivity make it an essential tool for quality assurance in manufacturing and maintenance processes.

Key application industries include:

-

Aerospace Industry:

Used extensively for inspecting aircraft components such as turbine blades, engine parts, landing gear, and structural assemblies, where safety-critical surface integrity is mandatory.

-

Automotive Manufacturing:

Ideal for detecting surface cracks and porosity in engine parts, transmission components, welded joints, and castings, helping ensure vehicle reliability and performance.

-

Oil and Gas Sector:

Employed for inspection of pipelines, valves, flanges, and pressure vessels to detect corrosion and weld defects that could lead to leaks or failures.

-

Power Generation:

Used for inspecting turbines, boilers, and heat exchangers to maintain operational safety and efficiency.

-

Heavy Machinery and Equipment:

Suitable for examining forged and machined parts, welds, and structural components to prevent premature failure and extend service life.

-

Shipbuilding and Marine Industry:

Critical for detecting surface discontinuities in hull structures, propellers, and other marine components exposed to harsh environments.

-

General Metal Fabrication:

Applicable in quality control of castings, forgings, and weldments across a wide range of industrial manufacturing processes.

This system enhances defect detection accuracy while streamlining inspection workflows, making it a valuable asset for companies committed to upholding stringent quality standards and regulatory compliance.

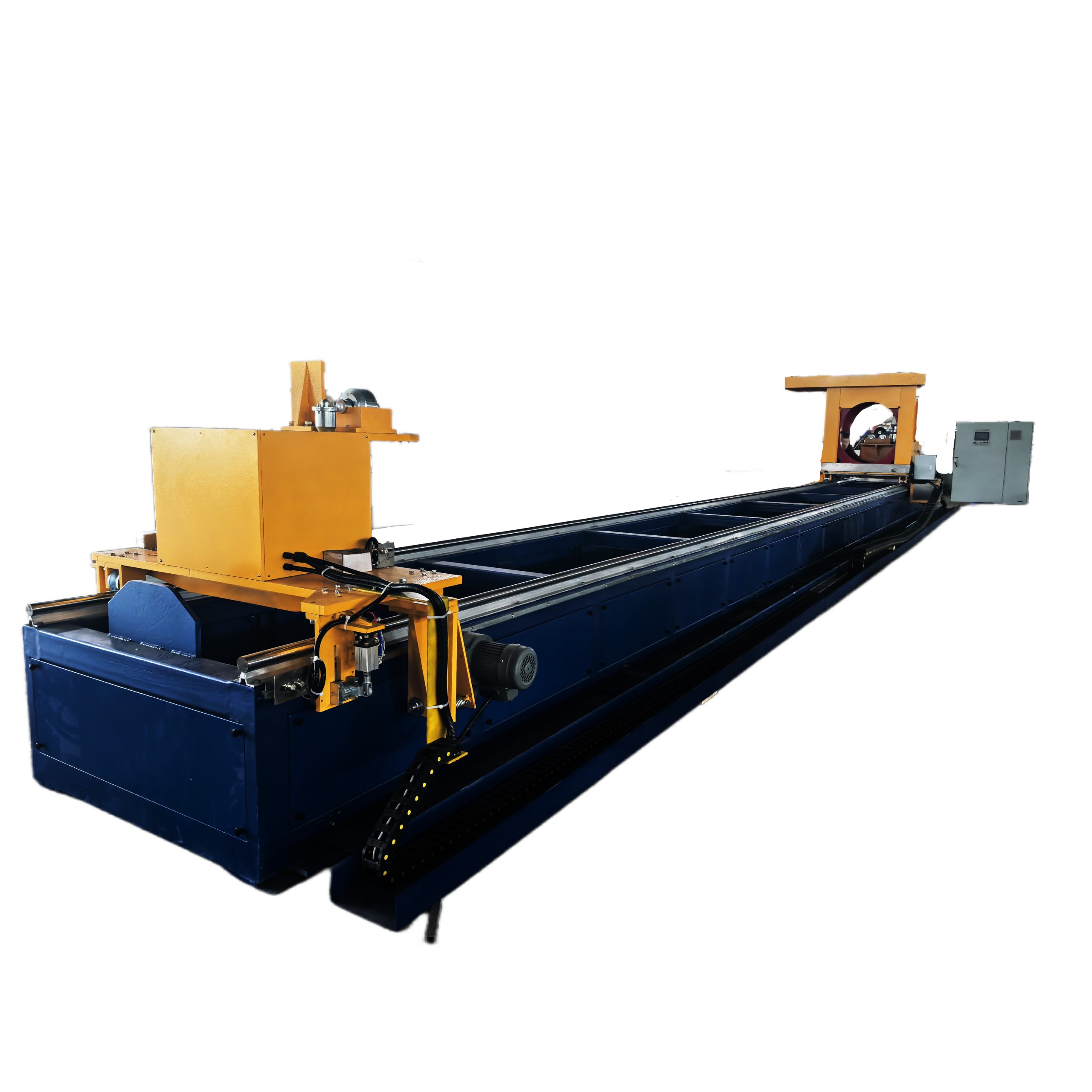

Semi-Automatic Fluorescent Penetrant Inspection Line for Non-Destructive Testing (NDT)

Nuke Non – Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle flaw detectors, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users. Contact us for more solutions.