The CT750 Steel Pipe Demagnetizer is a highly effective solution for a wide range of industries that require precise magnetic demagnetization of steel pipes and fittings. This system is used in various sectors where eliminating residual magnetism from steel components is crucial to maintaining product quality, operational efficiency, and equipment longevity. Below are the key application areas for the CT750 Steel Pipe Demagnetizer:

1. Steel Pipe Manufacturing

-

Components: Used for steel pipes, tubes, and fittings during production processes.

-

Benefits: Ensures that the finished steel pipes are free from unwanted magnetism, which could interfere with their subsequent processing, quality control, or handling in the supply chain.

2. Automotive Industry

-

Components: Applied to automotive parts such as axles, brake systems, steering components, and engine parts.

-

Benefits: Eliminates residual magnetism that could affect the performance of sensitive systems like ABS, sensors, and electronic controls, ensuring the safety and reliability of the final product.

3. Machinery and Heavy Equipment Manufacturing

-

Components: Used in the production of machinery parts, gears, shafts, bearing components, and hydraulic systems.

-

Benefits: Prevents interference in machinery performance due to magnetic contamination, thus extending the lifespan of components and enhancing the reliability of equipment.

4. Oil and Gas Industry

-

Components: Essential for steel pipes used in drilling and pipeline systems, especially in oil rigs, refineries, and gas pipelines.

-

Benefits: Ensures that the steel pipes are magnetism-free, which is critical in preventing damage or inaccuracies during fluid transportation and pressure testing.

5. Aerospace Industry

-

Components: Applied to aerospace parts including aircraft engine components, landing gears, control surfaces, and metal structures.

-

Benefits: In the aerospace sector, even minor magnetic interference can cause safety issues. The CT750 removes magnetism to ensure precise, magnetism-free parts for reliable and high-performance aircraft systems.

6. Electronics Manufacturing

-

Components: Used for metal parts in electronics like motors, transformers, magnetic sensors, and connectors.

-

Benefits: Removes residual magnetism that could affect the performance of electrical components, improving accuracy, functionality, and reducing the risk of malfunctions.

7. Construction and Infrastructure

-

Components: Demagnetizes steel components like reinforcement bars, steel girders, and structural parts.

-

Benefits: Ensures that the steel components used in construction and infrastructure projects are free from magnetic interference, maintaining structural integrity and the proper functioning of attached systems.

8. Medical Device Manufacturing

-

Components: Applied to medical device components like MRI equipment, surgical tools, and diagnostic machines.

-

Benefits: In the medical field, eliminating magnetism is critical for the accurate operation of equipment like MRI machines, where even small magnetic fields can affect the performance of imaging and diagnostics.

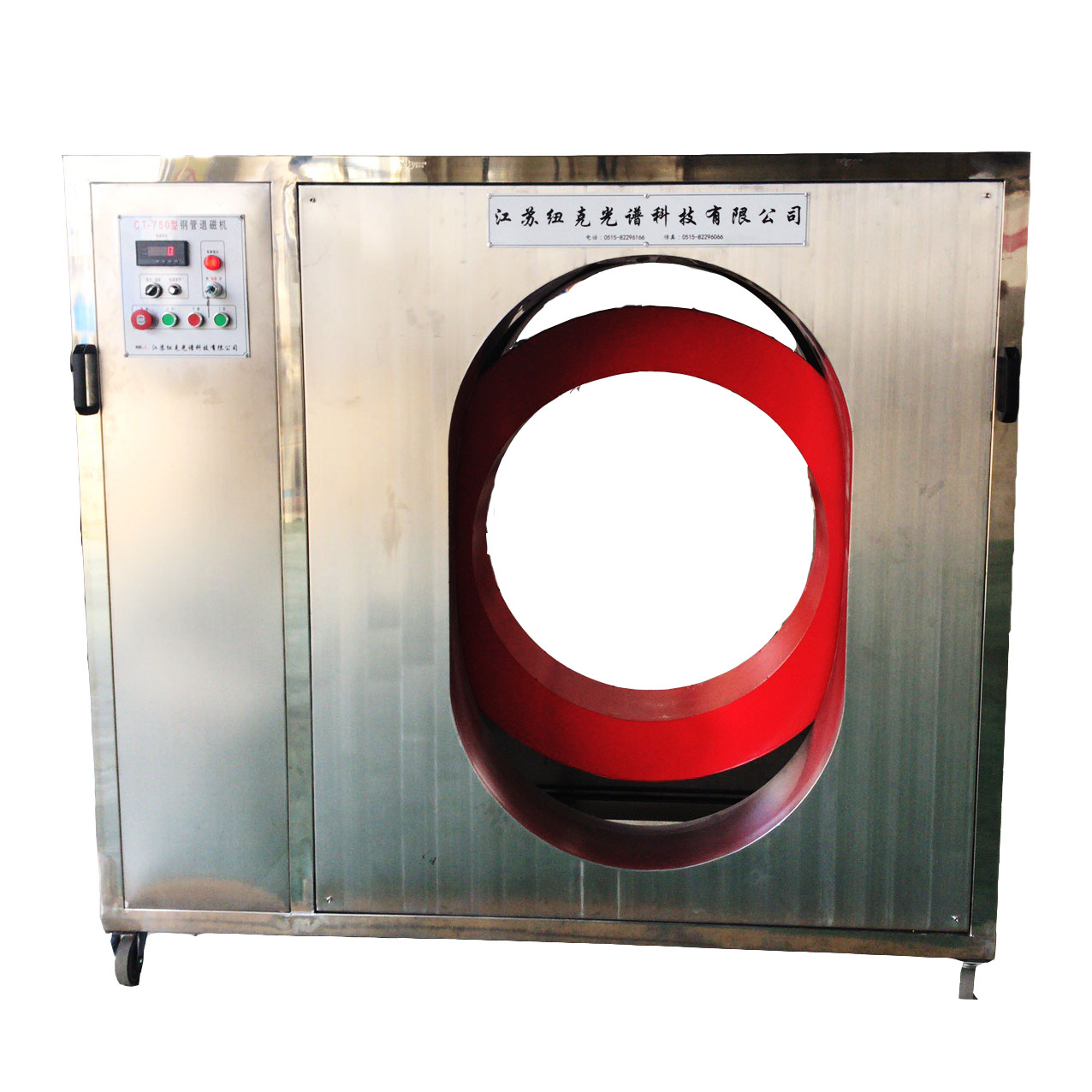

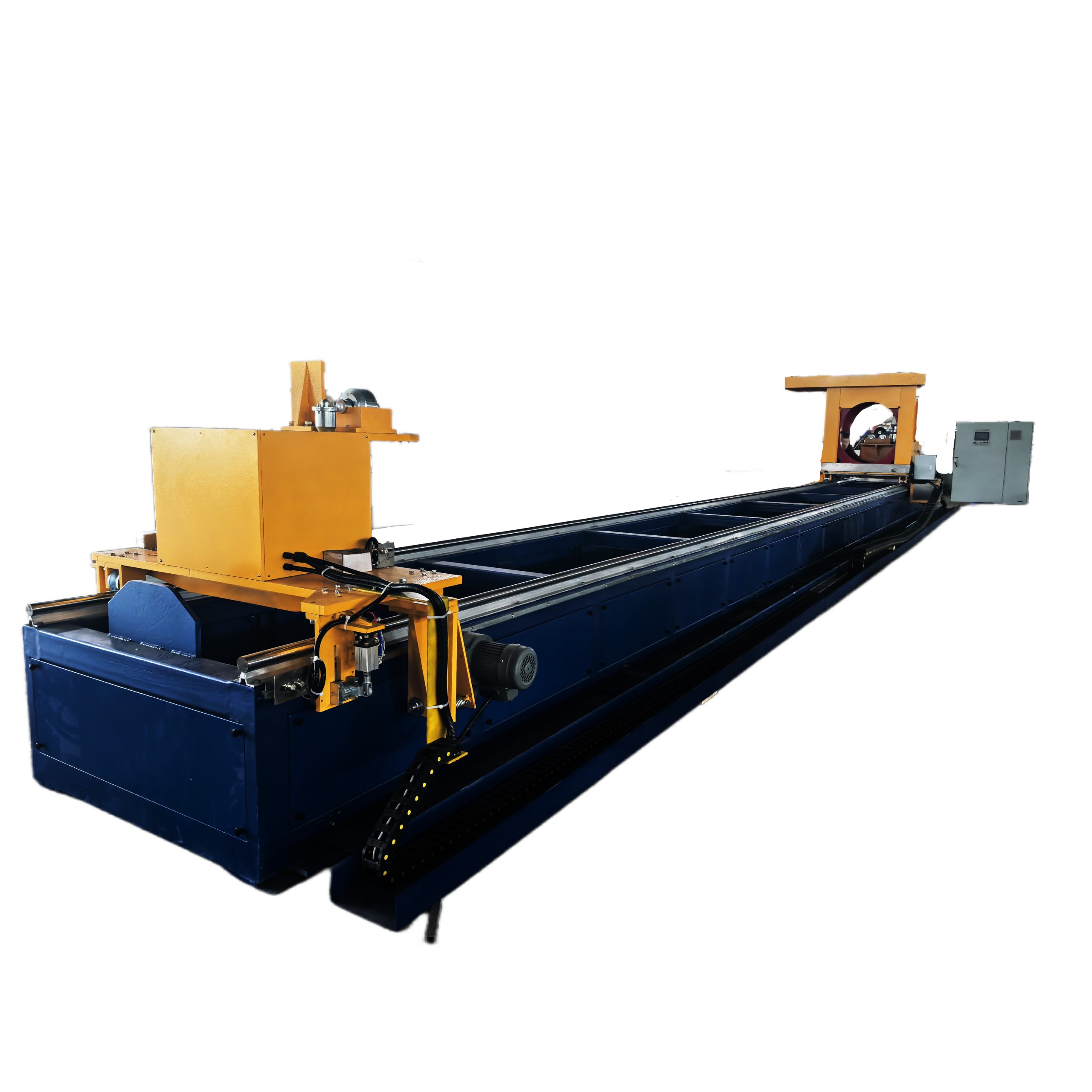

CT750 Magnetic Demagnetizer for Steel Tubes – Precision Demagnetization for Optimal Product Performance

Nuke Non–Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.