The CTG500 Demagnetizer System is a versatile and highly effective tool designed to cater to a wide range of industrial applications. Its primary function is to eliminate residual magnetism from metal parts, ensuring precision and high-quality standards across several industries. Below are the key application areas for the CTG500 Demagnetizer:

1. Automotive Industry

-

Components: Used for demagnetizing automotive parts such as axles, brakes, steering parts, engine components, and transmission parts.

-

Benefits: Ensures critical components are free of unwanted magnetism, preventing interference with the operation of sensitive electronic systems like ABS, airbags, and sensors. This helps improve the vehicle’s overall safety and reliability.

2. Machining & Precision Engineering

-

Components: Ideal for machined metal parts, tools, bearing components, gears, and shafts.

-

Benefits: Helps ensure the precision and longevity of machined parts by removing magnetic interference that could affect accuracy and the performance of CNC machines or other automated systems.

3. Electronics Manufacturing

-

Components: Used for demagnetizing electronic parts such as circuit boards, connectors, motors, and magnetic sensors.

-

Benefits: Ensures that sensitive electronic parts are magnetism-free, reducing the risk of malfunctions or inaccurate readings, and improving the overall quality of the electronic products.

4. Aerospace Industry

-

Components: Applies to aircraft parts, engines, landing gears, and control surfaces.

-

Benefits: In aerospace, even minor defects or magnetic interference can lead to catastrophic failures. The CTG500 ensures high-precision components are magnet-free, contributing to the overall safety and performance of the aircraft.

5. Medical Device Manufacturing

-

Components: Essential for demagnetizing parts used in medical devices, such as MRI machines, surgical instruments, and diagnostic tools.

-

Benefits: Helps maintain the high level of precision and safety required in the medical field, especially for equipment that needs to avoid any magnetic interference for accurate diagnostics or treatment.

6. Tool & Die Manufacturing

-

Components: Ideal for tools, molds, dies, and cutting instruments used in manufacturing.

-

Benefits: Demagnetizing tools and dies ensures longer tool life and prevents magnetic buildup that can cause problems with workpiece handling or product defects.

7. Heavy Machinery & Industrial Equipment

-

Components: Used in industries dealing with heavy machinery, such as construction equipment, mining machinery, manufacturing parts, and metalworking tools.

-

Benefits: Helps in preventing equipment malfunction or failure caused by unwanted magnetism, ensuring smooth, uninterrupted production and reducing maintenance costs.

8. Military and Defense Applications

-

Components: Used for demagnetizing parts used in military equipment, including vehicles, weapons systems, and communications devices.

-

Benefits: Ensures critical military components are free from magnetic interference, which is essential for the performance of navigation and communication systems.

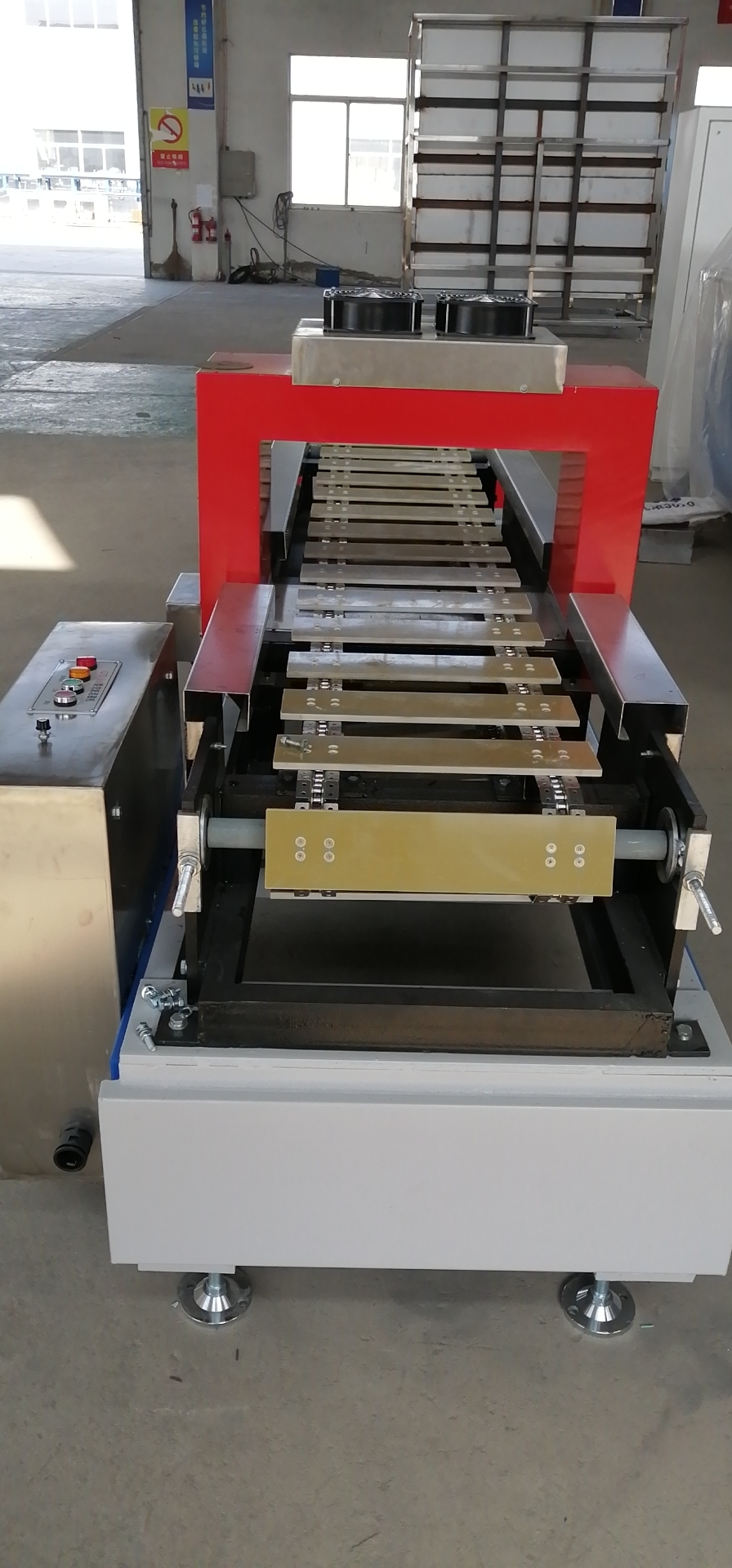

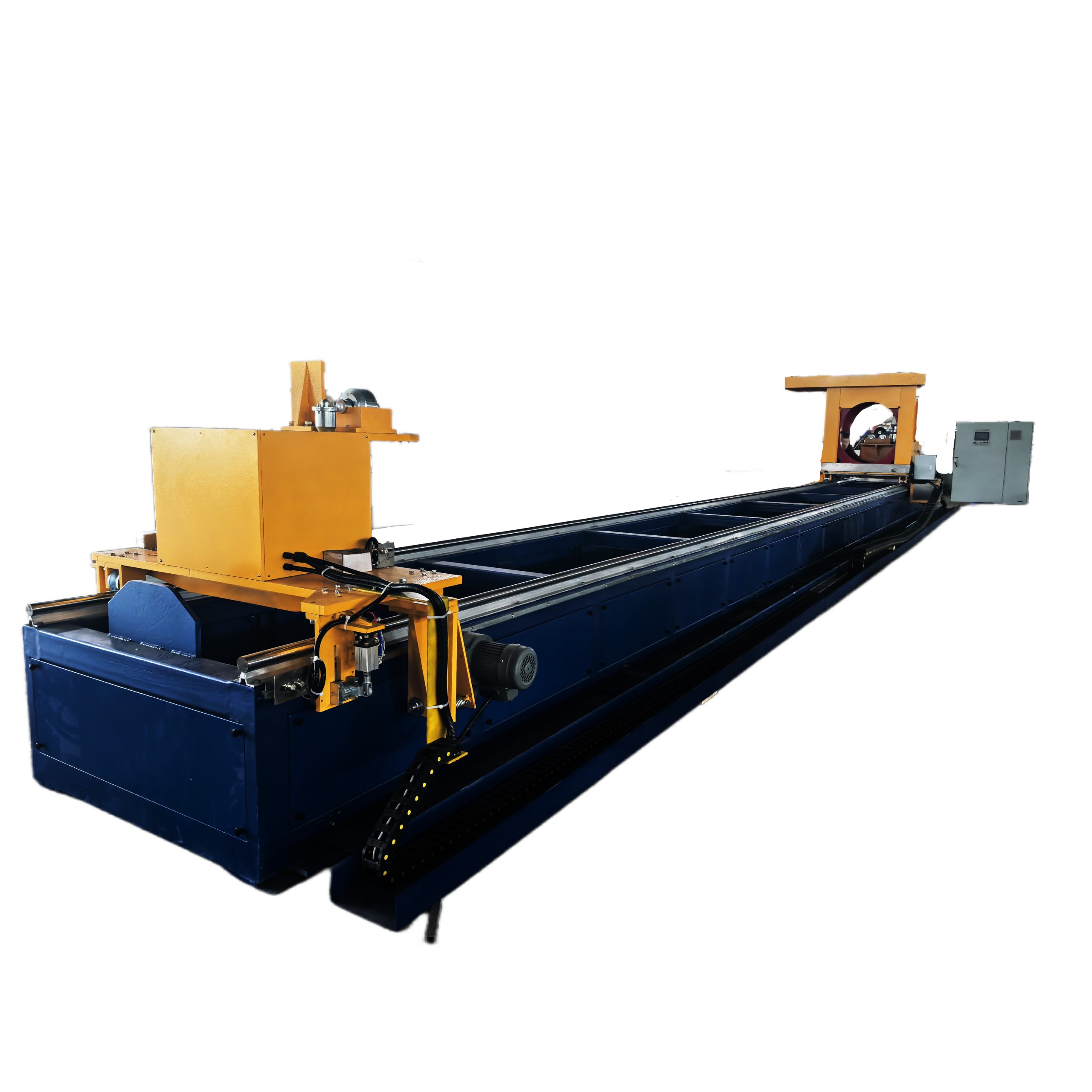

CTG500 Professional Demagnetization System for Precision Engineering & Manufacturing Parts

Nuke Non–Destructive Testing Co., Ltd. is a key high – tech enterprise specializing in the research, development, and sales of non – destructive testing equipment such as magnetic particle inspection machine, magnetic particle flaw detection instruments, demagnetizers, cleaning machines, penetrant flaw detectors, portable magnetic particle flaw detectors, and mobile magnetic particle flaw detectors.

The company adopts a modern enterprise management model and has established a complete manufacturing process and marketing service system for flaw detectors and detection instruments. Its products are designed with the aid of computer – assisted design, comply with the industry standard JB/T8290 – 1998 “Magnetic Particle Flaw Detectors”, and also refer to American MIL and German DIN standards. At present, these products are widely used in the non – destructive testing fields of industries including aerospace, aviation, military industry, railway, automotive, oilfield, shipbuilding, boilers, pressure vessels, bearings, gears, springs, tractors, diesel engines, motorcycles, power, chemical industry, standard parts manufacturing, and machinery manufacturing.

Relying on technological innovation and management innovation, the company continuously strengthens its core competitiveness and has won unanimous praise from users.