Understanding Industrial Cleaning Machines: Types, Applications, and Innovations

Industrial cleaning machines play a vital role in modern manufacturing and maintenance processes. From removing grease, oil, and metal shavings to preparing surfaces for further processing, these machines ensure operational efficiency, product quality, and compliance with safety standards. In this article, we explore the fundamentals of industrial cleaning systems, their various types, core applications, and recent technological advancements — offering a comprehensive guide for engineers, buyers, and industry professionals alike.

🔧 What Is an Industrial Cleaning Machine?

An industrial cleaning machine is specialized equipment designed to clean mechanical parts, tools, or surfaces using mechanical, chemical, thermal, or physical methods. These machines are essential in industries that require high cleanliness standards, such as aerospace, automotive, electronics, precision manufacturing, petrochemicals, shipbuilding, and more.

🧼 Common Types of Industrial Cleaning Machines

Depending on the cleaning medium and application requirements, there are several common types of cleaning machines:

1. High-Pressure Cleaning Machines

These machines use water jets at extremely high pressure (up to 3000 bar or more) to remove paint, rust, scale, and deposits. Commonly used in heavy industries like shipbuilding, pipelines, and power plants.

2. Ultrasonic Cleaning Machines

Ideal for precision parts, ultrasonic cleaners use high-frequency sound waves to create microscopic cavitation bubbles in a cleaning liquid. These bubbles scrub complex surfaces, including internal holes and crevices, without damaging the component.

3. Spray Washing Machines

Utilizing a combination of heated water, detergents, and mechanical spray action, these are commonly used for automotive parts, tools, and manufacturing components.

4. Immersion & Agitation Cleaners

Parts are submerged in a tank containing cleaning fluid. Agitation (via bubbles, vibration, or movement) enhances cleaning effectiveness. Suitable for degreasing and removing fine particles.

5. Laser Cleaning Machines

A modern solution that uses laser beams to remove contaminants from surfaces with high precision. It’s non-abrasive, environmentally friendly, and ideal for delicate components or historical restoration.

6. Dry Ice Blasting Machines

Using CO₂ pellets at high velocity, dry ice cleaning is a non-conductive and residue-free method that’s gaining popularity in food processing, electronics, and mold cleaning.

🏭 Applications Across Industries

Industrial cleaning equipment is indispensable across numerous industries:

-

Automotive: Engine blocks, transmission components, fuel injectors

-

Aerospace: Aircraft parts, turbine blades, landing gear components

-

Petrochemical: Pipeline maintenance, reactor cleaning

-

Shipbuilding: Hull cleaning, rust removal

-

Electronics: Circuit boards, semiconductor wafers

-

Fastener Manufacturing: Bolt and nut degreasing and polishing

Clean parts ensure better adhesion, painting, coating, welding, and longer equipment lifespan.

🚀 Key Features to Look for in Modern Cleaning Machines

-

Automation & Programmability: PLC-controlled systems reduce manual labor and ensure consistent results.

-

Energy Efficiency: Heat recovery systems and optimized fluid usage reduce operating costs.

-

Eco-Friendliness: Compliance with environmental standards by using biodegradable chemicals or no chemicals at all.

-

Modular Design: Enables flexible configuration based on customer requirements.

-

Safety: Features like emergency stop systems, protective enclosures, and operator training reduce risk.

🌍 Global Demand and Export Potential

With the global shift toward greener manufacturing and stricter quality control, demand for advanced industrial cleaning machines continues to grow — especially in emerging markets like Southeast Asia, the Middle East, and Latin America. Export-oriented manufacturers offering CE/ISO-certified, customizable, and energy-efficient cleaning equipment are gaining a significant edge in the international market.

🤝 Why Choose Us?

At [Your Company Name], we bring years of expertise in delivering tailored cleaning solutions for a wide range of industries. Our product line includes:

-

High-pressure cleaning systems

-

Ultrasonic cleaning machines (standard and custom-built)

-

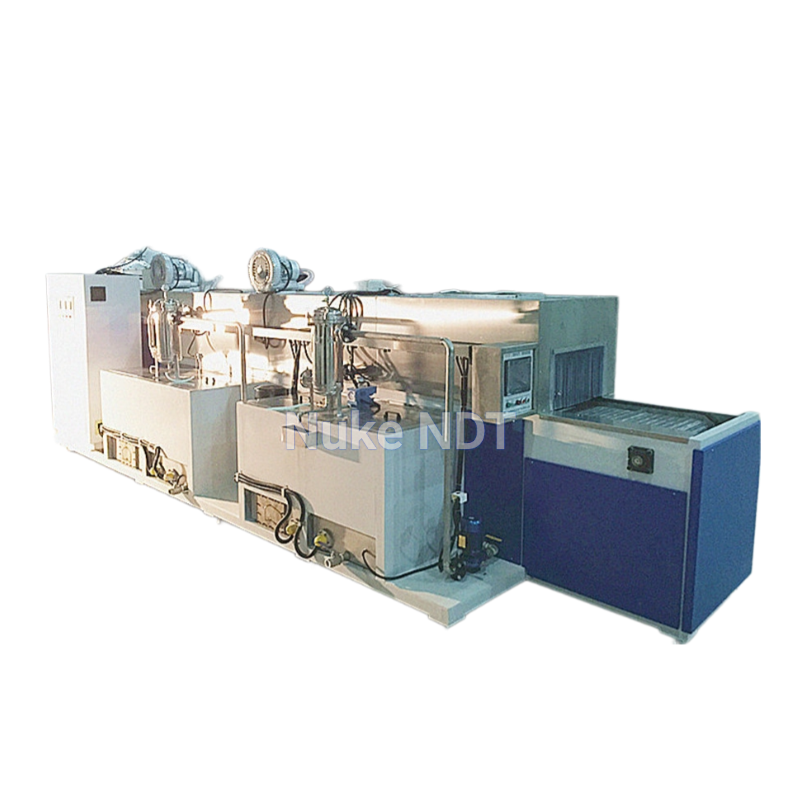

Fully automated cleaning lines for mass production

-

Portable and stationary cleaning units

-

Laser and dry ice cleaning technologies (available on request)

We focus on efficiency, safety, and environmental compliance, helping customers improve productivity while reducing costs and waste. All our equipment can be customized to meet specific industry needs and regulatory requirements.

📞 Let’s Work Together

Looking for a reliable partner for your cleaning system needs?

Contact us to learn more about how our equipment can support your production process.